Have you ever handed over a cherished necklace for restringing, only to find it returns with a loose knot or, worse, a broken chain? That sinking feeling when your favorite jewelry loses its luster because of a simple mistake early in the repair process is all too familiar to me. I used to think that a quick fix was enough, but I learned the hard way that trust in jewelry repair is built on attention to detail and quality craftsmanship. Today, I want to share how mastering the art of restringing and jewelry repair can turn a frustrating experience into a lasting relationship of trust with your clients and loved ones.

The Power of Proper Restringing in Building Trust

When it comes to jewelry, a well-done repair isn’t just about fixing a broken clasp; it’s about restoring confidence. A necklace that sits perfectly, with secure knots and durable materials, becomes more than just jewelry—it’s a symbol of care and trust. Early in my career, I made the mistake of rushing through restringing, thinking that a quick fix was good enough. That mistake cost me a loyal customer and my reputation for quality. Since then, I’ve learned that every detail matters, from choosing the right stringing material to knotting techniques that prevent future damage. If you’re eager to build lasting trust with your clients, understanding these nuances is essential. For more insights on how to approach this, check out my guide on resstringing to build trust and lasting value.

Is Restringing Actually Worth the Hype?

Some skeptics believe that restringing is just a cosmetic fix—something that can be done quickly and cheaply. But I’ve seen firsthand how the right techniques can extend the life of jewelry and reinforce trust. A poorly strung necklace can unravel after just a few wears, leading to customer dissatisfaction. My early mistake was choosing cheap cord because I thought it was enough. Turns out, quality materials and proper knotting are what truly make a difference. This realization prompted me to invest in training and proper tools, which paid off in customer confidence and repeat business. If you’re wondering whether investing time and effort into restringing is worth it, I say yes—when done right, it transforms not just the jewelry but the relationship you have with your customers. For expert tips on how to do this effectively, visit expert restringing tips for lasting trust.

Choose the Right Materials to Guarantee Durability

Start by selecting high-quality stringing materials suited for the jewelry piece. Think of it as choosing the right thread for a delicate embroidery—using inferior thread might save time initially but leads to unraveling down the line. I once used nylon cord for a client’s heirloom necklace, assuming it would hold up. After a few wears, the cord frayed, and the customer was disappointed. Since then, I always opt for silk or nylon-coated beading wire for strength and flexibility. To deepen your understanding, check out expert restringing tips for lasting trust.

Master Knotting Techniques for Security

Proper knotting is the backbone of a reliable restringing process. I remember a time I was in a rush during a busy day and skipped meticulous knotting. The necklace unraveled after just a few wears, costing me both time and trust. Now, I use the surgeon’s knot or double knot techniques, ensuring each knot is tight and neat. Think of it as tying shoelaces—firm, neat knots prevent slipping. When you master these, your jewelry won’t just look good; it will last. For detailed guidance, explore expert knotting methods.

Implement Consistent Tension During Stringing

Maintaining even tension while restringing prevents slack or over-tensioning, which can cause breakage. I once worked on a vintage pearl necklace and noticed uneven tension caused pearls to sit crooked. I fixed this by pulling gently and consistently as I threaded each bead, like tightening a cable with uniform pressure. This step might seem small but makes a huge difference in appearance and durability. Use a beading board or a steady hand to keep tension even. For visual tips, see restringing tension tips.

Secure the Clasp Properly to Prevent Loss

The clasp is the final line of defense against losing your jewelry. I learned this lesson when a clasp came loose because I didn’t crimp or secure it properly. Now, I double-check each clasp, making sure it’s tightly closed and the jump ring is securely crimped. Think of it like locking a door—if it’s not properly secured, everything inside is at risk. Using crimp beads and pliers, I make sure the clasp is tight and smooth. For a detailed walkthrough, review clasp securing techniques.

Test Your Work Before Returning to the Client

Before handing over the finished piece, always test its strength by gently tugging and inspecting each connection. I once finished restringing a bracelet and, in my rush, skipped the final test. After a day, a bead popped loose. Now, I always give the piece a thorough shake and visually inspect every knot and connection. It’s like test-driving a new car—making sure everything runs smoothly before the customer does. This extra step builds confidence and trust. For more on quality checks, see quality assurance in jewelry repair.

Many jewelry enthusiasts and even seasoned repairers believe that focusing solely on the visible aspects of restringing—like choosing the right beads or making neat knots—is enough to ensure a durable, trustworthy piece. However, this overlooks some critical nuances that can make or break the longevity and trustworthiness of your work. Let’s dig deeper into what most people get wrong and how mastering these subtle details can elevate your craftsmanship.

Why the Material Choice Isn’t Just About Appearance

It’s a common misconception that the most visually appealing stringing material always offers the best durability. While aesthetics matter, the true secret lies in understanding the material’s properties—elasticity, tensile strength, and chemical compatibility with the beads or metals. For example, some synthetic cords may look great but degrade faster when exposed to sunlight or moisture. Conversely, natural silk might offer superior flexibility and longevity when paired with the right knotting techniques. To deepen your knowledge, explore expert restringing tips for lasting trust.

Mastering the Art of Knot Tension to Prevent Slippage

Many repairers focus on tying secure knots but forget that inconsistent tension during restringing can cause future issues. Too tight, and the string may weaken or break; too loose, and knots can slip, jeopardizing the piece’s integrity. Advanced craftsmen use tension guides or even specialized tools to maintain uniform tension throughout the process. This attention to detail ensures the knots are not just secure but optimized for durability. Curious about the advanced knotting techniques? Check out expert knotting methods.

What Is the Real Impact of Crimping and Clamping?

It’s not enough to just close a jump ring or crimp a bead; the quality of the crimping process determines whether the clasp stays secure over time. Many get this wrong by using worn-out pliers or applying uneven pressure, leading to slippage. The secret is in using the right tools—precision crimping pliers—and applying consistent, firm pressure. This ensures the clasp is not just attached but permanently secured. For a detailed walkthrough, review clasp securing techniques.

How One Small Oversight Can Undermine Your Work

Overlooking final testing is a trap many fall into. A piece might look perfect but can unravel unexpectedly if even one knot or connection isn’t properly tested under stress. I’ve seen professionals skip the tug test, only for the customer to return with a broken strand. The lesson? Always perform a thorough stress test—gently tug, shake, and visually inspect every connection. This small step can save you from costly rework and guarantees your reputation for quality. For more on quality assurance, see quality checks in jewelry repair.

Have you ever fallen into this trap? Let me know in the comments, and share your own experiences with the nuances that made a difference in your work. Remember, mastering these hidden details is what separates good repairers from great ones—and builds lasting trust with your clients.

Maintaining your jewelry repair tools is crucial to ensure precision and longevity in your craft. Over time, even the best tools can wear out or become less effective if not properly cared for. I personally recommend investing in high-quality pliers like the Kuhn brand, known for their durability and slip-resistant grips, which provide better control during crimping and knotting. Regularly cleaning your pliers with a soft cloth and avoiding moisture prevents rust and keeps their tips sharp. Proper maintenance of tools contributes significantly to consistent results and builds trust with your clients.

For measuring tension accurately during restringing, I rely on a digital tension gauge. This device helps me maintain uniform tension, which is vital for durability. It’s a small investment but pays off by preventing future issues like slippage or breakage. Additionally, I keep a beading mat on my workspace; it prevents beads from rolling away and protects delicate components, saving time and frustration. These small but essential tools make a noticeable difference in the quality of your work.

How do I keep my tools in top condition over time?

To prolong the life of your tools, clean them after each use with a gentle brush or cloth. Store them in a dedicated tool case or organizer to prevent damage, and avoid leaving them in humid environments. Periodic lubrication of hinges and joints with a light machine oil keeps them operating smoothly. For example, using WD-40 Specialist can prevent rust and keep your pliers functioning like new. Remember, well-maintained tools not only improve your craftsmanship but also reduce the risk of damaging jewelry during repairs.

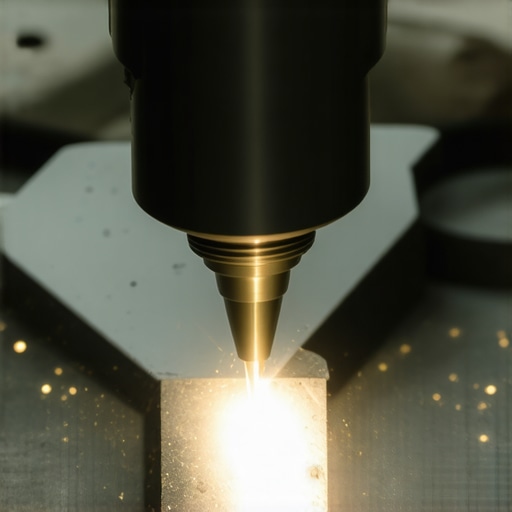

Looking ahead, I believe that automation and digital tools will become more integrated into jewelry repair workflows, offering enhanced precision and efficiency. For now, mastering manual tools and proper maintenance remains the foundation of a reliable repair operation.

Try implementing a regular cleaning and lubrication routine for your tools this week. It’s a simple step that can significantly improve your results and boost your confidence. Proper maintenance isn’t just about preservation — it’s about investing in your craft and ensuring your repairs stand the test of time. For more advanced tips on tool care, explore expert tool maintenance strategies.

Lessons That Changed How I Repair Jewelry

- Patience Pays Off: Rushing through restringing may seem efficient, but I learned that taking my time with proper knotting and tension creates pieces that last and customers trust.

- Quality Materials Are Non-Negotiable: Switching from cheap cords to silk or coated beading wire dramatically increased the durability of my repairs and boosted client confidence.

- Final Testing Is a Game Changer: Gently tugging and inspecting each connection before returning jewelry prevents surprises and shows professionalism.

- Attention to Detail Matters: Small steps, like securing clasps with crimp beads and maintaining even tension, make the difference between a good repair and a trusted craft.

My Top Tools and Resources for Jewelry Repair

- High-Quality Pliers: Brands like Kuhn are reliable, durable, and provide precision for crimping and knotting—crucial for lasting repairs. Regular cleaning keeps them sharp and rust-free.

- Digital Tension Gauge: Ensures consistent tension during restringing, preventing breakage or slippage. It’s a small investment that pays off in quality assurance.

- Beading Mats: Protect delicate components and keep beads organized, saving time and reducing frustration during repairs.

- Expert Guides: Resources like this guide offer invaluable tips that elevate your craftsmanship and client trust.

Your Craftsmanship Can Truly Shine

Every jewelry repair is an opportunity to demonstrate your dedication to quality and trust. When you master the nuances of restringing—from material choice to knot tension and final testing—you’re not just fixing jewelry; you’re building lasting relationships with your clients. Keep refining your skills, invest in quality tools, and remember that attention to detail is the secret ingredient for success. Your journey toward becoming a trusted expert in jewelry repair starts today—embrace each step with care and confidence. What’s the most challenging part of your restringing process? Share your experience below and let’s grow together.

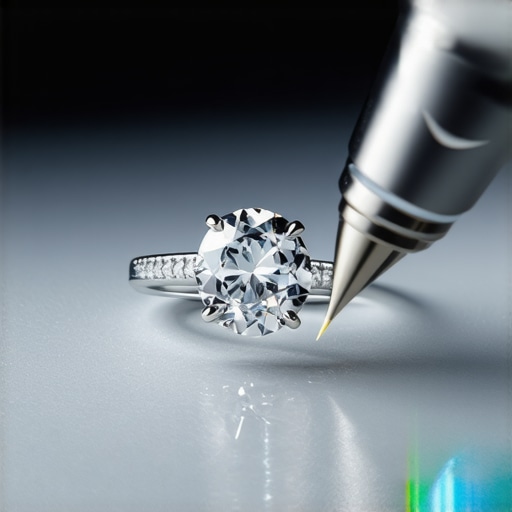

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)