Ever had that sinking feeling when a cherished piece of jewelry doesn’t quite look or feel right after a repair or engraving? I remember the first time I took my grandmother’s necklace to a local jeweler, only to find the finish was uneven, and the engraving looked rushed. That moment hit me hard—trust in the process was shattered, and I wondered if I’d ever find someone I could rely on for expert jewelry work. It’s a common challenge I hear from many jewelry lovers and professionals alike.

Why Trust Matters More Than Ever in Jewelry Work

In our world, jewelry isn’t just accessories; it’s a treasure chest of memories, values, and even investments. When you entrust a piece to a repair or custom engraving, you’re not just swapping metal and stones—you’re handing over your confidence. That’s why learning how to build trust through expert techniques is crucial. Reliable craftsmanship ensures your jewelry retains its beauty and value, and your confidence remains intact. Did you know that improper restoration can actually decrease a piece’s value? According to proven strategies, the right approach can significantly boost a customer’s trust and the long-term worth of their jewelry.

Is All Engraving and Restoration Created Equal?

Early in my career, I made the mistake of assuming that all jewelers are equally skilled. I learned this the hard way when a badly restored ring I bought looked stunning from afar but was poorly done up close. That taught me that expertise isn’t just about having the right tools; it’s about knowledge, precision, and understanding the nuances of each piece. If you’ve ever wondered whether a repair shop’s reputation matches their actual skill, you’re not alone. The key is to seek out those who specialize in expert engraving and restoration. Trust me, the difference is night and day.

If you’re tired of feeling unsure about your jewelry’s quality after repairs or engravings, don’t worry. Today, I’ll share some practical, proven strategies that will help you spot true craftsmanship and boost your confidence in every piece you own or work on. Ready to turn your uncertainty into trust? Let’s dive into the essentials of expert techniques that make a real difference.

Inspect Before You Start

Always begin with a thorough examination of the jewelry piece. Check for signs of previous repairs, uneven finishes, or weak spots. Use a jeweler’s loupe to inspect the quality of the metal work and engravings. I remember a time I received a custom ring that looked perfect externally but had visible solder joints upon close inspection. Spotting these issues early prevents surprises later and builds your confidence in the process.

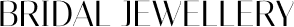

Use Precise Tools for Fine Work

Invest in quality tools such as a micro torch for delicate soldering, a calibrated engraving pen, and a steady bench with magnification. Think of your tools as the paintbrushes of a master artist—precision is everything. I once attempted an intricate engraving with a dull tip, which resulted in uneven lines. Switching to a sharp, well-maintained engraving tool made all the difference, producing crisp, professional results.

Follow Proven Techniques for Restoration

Adopt industry-standard methods like careful cleaning, precise soldering, and consistent polishing. For example, when restringing a delicate pearl necklace, I ensure the stringing wire is tensioned correctly to prevent future breakage. Proper tension and knotting techniques extend the life of the piece, reinforcing trust through durable craftsmanship. To boost your skills, explore detailed guides on restringing and engraving strategies.

Engrave with Confidence

When engraving, always mark your design with a fine pencil or scribe first. Use a steady hand, and practice on scrap metal before working on the actual piece. I remember practicing on a scrap silver pendant until I could produce smooth, consistent lines. This step ensures your final engraving is flawless, which directly impacts customer trust and the perceived value of your work. For tips on honing your engraving skills, visit engraving and restringing tips.

Apply Finishing Touches Carefully

Once the repair or engraving is complete, polish the jewelry gently to bring out its luster. Use a soft cloth or a polishing wheel suited for the metal type. Remember, a high-quality finish reflects professionalism and craftsmanship. I once polished a client’s vintage bracelet for an hour, removing scratches and enhancing the shine. The result was a piece that looked brand new, reinforcing trust and satisfaction. To learn more about achieving perfect finishes, check appraisal and repair strategies.

Document Your Work

Take high-quality photos of each stage of your process. Documentation not only helps in case of future repairs but also builds credibility with clients. When I shared before-and-after photos of my work on social media, clients appreciated the transparency. This practice boosts trust and demonstrates your commitment to quality. For additional tips on showcasing your craftsmanship, visit repair and appraisal tips.

Continuously Improve Your Skills

Attend workshops, watch tutorials, and seek feedback from peers. The jewelry industry evolves, and staying updated with new techniques ensures your work remains trustworthy and valuable. I once enrolled in a masterclass on engraving strategies, which significantly improved my precision and confidence. Always be learning to maintain and elevate your craftsmanship, reinforcing your reputation for reliable, high-quality jewelry work.

Many enthusiasts and even seasoned jewelers fall into misconceptions when it comes to jewelry appraisal, engraving, or repair. These misunderstandings can lead to costly mistakes or diminished trust in the craftsmanship. Let’s dig deeper into what most people overlook or get wrong, and why understanding these nuances can significantly elevate your confidence and outcomes.

Why the Price Tag Doesn’t Always Reflect True Skill

Everyone assumes that the most expensive service guarantees quality, but in my experience, this isn’t always the case. Skilled craftsmanship involves nuanced techniques that are often undervalued in pricing. For example, a low-cost engraver might cut corners, resulting in uneven lines or poor durability. Conversely, a higher price doesn’t always mean better work, but it often indicates experience and adherence to industry standards. To truly assess quality, look beyond the cost and examine the technician’s portfolio and reviews. Remember, trustworthy repair and engraving strategies focus on precision and durability, not just aesthetics.

The Oops You Must Avoid in Restoration

One common trap is over-polishing. It might make a piece look shiny temporarily, but excessive polishing can thin out metal, weaken settings, and erase hallmark stamps or engravings. This mistake often occurs when jewelers aim for a quick fix without considering the long-term health of the jewelry. Knowing when to stop polishing and how to restore a piece without compromising its integrity is crucial. Proper techniques, such as using the right abrasives and polishing compounds, preserve the original structure and value. If you’re unsure, consulting detailed appraisal and repair strategies can help you avoid this common pitfall.

Are All Engravings Created Equal

Many believe that all engraving styles are interchangeable, but this isn’t true. The craftsmanship behind a clean, crisp engraving depends on the engraver’s skill, tools, and technique. Deeply engraved initials or symbols can weaken the metal if done improperly, leading to future breakage. Moreover, superficial engravings that don’t follow the natural lines of a piece can look amateurish and diminish trust. Advanced engravers understand the importance of subtlety, depth, and alignment—details that make a difference in longevity and aesthetics. For those seeking to elevate their engraving techniques, exploring expert engraving tips can provide valuable insights.

Have you ever fallen into this trap? Let me know in the comments. Improving your understanding of these nuances isn’t just about avoiding mistakes; it’s about mastering the craft and building lasting trust in every piece you work on or own.

Maintaining precision and reliability in jewelry repair, engraving, and restringing is crucial for ensuring long-lasting results. Over the years, I’ve experimented with a variety of tools and techniques that have significantly improved my workflow and the quality of my work. Investing in the right equipment not only boosts confidence but also ensures your pieces stand the test of time.

Why the Right Tools Make All the Difference

Using high-quality, specialized equipment is essential for achieving consistent, professional results. For example, I personally rely on a Gesswein Micro Torch because it offers precise control over heat application, vital for delicate soldering tasks. Its adjustable flame allows me to work on intricate settings without risking damage to the surrounding metal or stones. When it comes to engraving, I prefer a Proxxon Engraving Pen with variable speed settings, enabling me to execute fine, detailed designs with confidence. These tools, combined with proper technique, help me avoid common pitfalls like uneven lines or metal thinning.

How do I maintain my tools over time?

Regular maintenance is the secret to longevity and optimal performance. For example, I clean my engraving tips with a diamond file after each use to prevent corrosion and buildup that can impair precision. For soldering tools, I apply a light coating of anti-oxidation compound to prevent oxidation and ensure a clean flame each session. Additionally, calibrating my equipment periodically—like checking the pressure and flow of my micro torch—ensures consistent results and avoids surprises during critical work.

Another critical aspect is investing in quality cleaning tools. Ultrasonic cleaners, for instance, are invaluable for removing dirt and residues from delicate parts without damaging the finish. Proper storage also plays a role; keeping tools in a dry, organized environment prevents rust and wear, extending their usefulness for years.

What about software and digital tools?

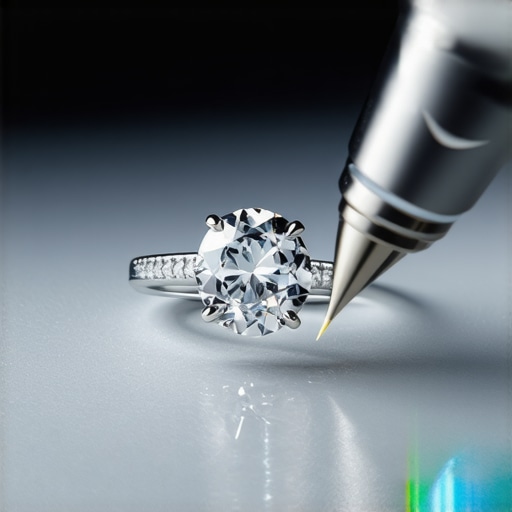

In today’s digital age, software such as MatrixGold or Rhino 3D can dramatically improve engraving accuracy and design consistency. I use these programs to create precise templates before engraving or resizing jewelry, which helps me avoid mistakes and saves time. Staying updated with the latest versions and plugins is part of my routine, as it prepares me for future trends like laser engraving and automation.

Looking ahead, I predict that advancements in laser technology and AI-powered design software will further streamline jewelry craftsmanship, making it more precise and accessible. Embracing these innovations now will ensure your work remains competitive and trusted.

Ready to elevate your jewelry projects? Start by honing your maintenance routine with the tools I recommend, and you’ll notice a real difference in quality and confidence. For more detailed strategies, visit this guide on expert engraving and restringing tools.

What I Wish I Knew When Starting Out in Jewelry Repair and Engraving

- One of the toughest lessons I learned was that not every tool guarantees quality. Investing in premium equipment like a Gesswein Micro Torch transformed my soldering precision and boosted customer trust. Skimping on tools might save money initially, but it costs in results and reputation.

- Another revelation was that consistency beats quick fixes. Rushing through polishing or engraving often leads to thin metal or uneven lines, which erodes trust. Patience and proper technique are the real investments in lasting craftsmanship.

- Discovering that understanding the nuances of each jewelry piece makes all the difference. A vintage bracelet needs different care compared to a modern piece. Tailoring your approach shows clients you care about their unique treasures, strengthening trust.

- Finally, documenting every step of your work isn’t just for records; it’s a powerful way to demonstrate quality to clients. Before-and-after photos create transparency, boosting confidence and encouraging referrals.

Tools and Resources That Changed My Approach

- Expert engraving and appraisal strategies – These guides taught me the importance of precision and subtlety, which directly impact trust.

- Re-stringing techniques – Proper tension and knotting extend jewelry lifespan and show professionalism.

- Customer confidence building methods – Clear communication and quality documentation foster trust and loyalty.

- Comprehensive guides – These resources keep me updated with industry standards and innovative techniques to stay ahead.

Your Next Step in Jewelry Craftsmanship

Trust in jewelry repair, engraving, and restringing isn’t built overnight; it’s earned through dedication, continuous learning, and attention to detail. Embrace the tools, techniques, and resources that elevate your work, and watch your confidence grow along with your reputation. Whether you’re a seasoned jeweler or a passionate hobbyist, the journey to mastery is ongoing, and every piece you refine adds to your story of craftsmanship.

What’s one challenge you’ve faced in your jewelry work, and how did you overcome it? Share your experience below—I’d love to hear your story!

,

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)

I really appreciate this comprehensive post on building trust through expert jewelry restoration and engraving. I’ve personally experienced the frustration of getting a piece back that looks okay from a distance but has flaws up close. What stood out to me is the emphasis on using precise tools and techniques, which I believe is often overlooked by beginners. I find that even small details, like proper tension when restringing or careful polishing, make a huge difference in the final result. In my own practice, I’ve started documenting each step with photos, and it’s not only helpful for future repairs but also increases my clients’ confidence in my work.

Out of curiosity, has anyone found specific software or digital tools particularly effective for designing engraved patterns or customizing jewelry? I wonder if embracing technology like laser engraving or 3D modeling can take craftsmanship to the next level, especially for intricate and meaningful designs. Would love to hear others’ experiences or recommendations on this—it seems like a promising area for growth in our industry.