I remember the exact moment I realized I was inadvertently eroding my clients’ trust. A beautifully crafted necklace, a painstakingly engraved pendant—yet, when the piece came back after a repair, the customer hesitated, eyes flickering with doubt. That lightbulb moment hit hard: even the tiniest flaws in finishing or engraving can make or break confidence in our work.

It’s frustrating, isn’t it? You pour your skill and heart into each piece, but sometimes the perceived value and trust seem just out of reach. Over time, I learned that mastering technical skills like engraving and restringing isn’t just about aesthetics; they are powerful tools to *enhance* credibility and elevate the worth of your jewelry pieces. I want to share these insights because I know how transformative they can be, not only for your reputation but for the confidence of your customers.

Today, I promise to walk you through proven techniques that boost trust and increase the value of your jewelry repairs and customizations. Whether you’re just starting out or looking to refine your skills, knowing how to expertly engrave or restring can set you apart in this competitive field.

Why Precision in Engraving and Re-stringing Matters More Than Ever

In our line of work, details speak volumes. A clean, precise engraving or a secure, well-done restringing can make clients see us as true artisans—trustworthy, meticulous, and committed to quality. But let’s be honest: early on, I made the mistake of rushing through these details, assuming they weren’t that critical. Big mistake. It was only after I faced disappointed clients and lost potential repeat business that I appreciated how these subtle touches elevate a simple repair into a masterpiece.

The good news? Developing expertise in engraving and restringing isn’t as intimidating as it seems. With the right techniques and attention to detail, you can turn every piece into a testament of your craftsmanship. Plus, these skills align perfectly with broader efforts like enhancing jewelry confidence and trusting appraisal values—topics I often explore in my articles, such as the [best tips to build lasting trust and confidence in jewelry](https://jewelryfixpro.com/restringing-jewelry-repair-build-trust-confidence-today).

So, have you ever felt unsure about your engraving or restringing skills? Or worried that a flawed finish might diminish your client’s trust? Rest assured, you’re not alone. Many of us face this challenge, but the good news is that mastering these techniques can be a game-changer.

In the sections ahead, I’ll share actionable strategies to refine your craft, avoid common pitfalls, and ensure every piece you work on radiates quality and trust. Let’s dive into the practical steps that will transform your jewelry service from good to unforgettable.

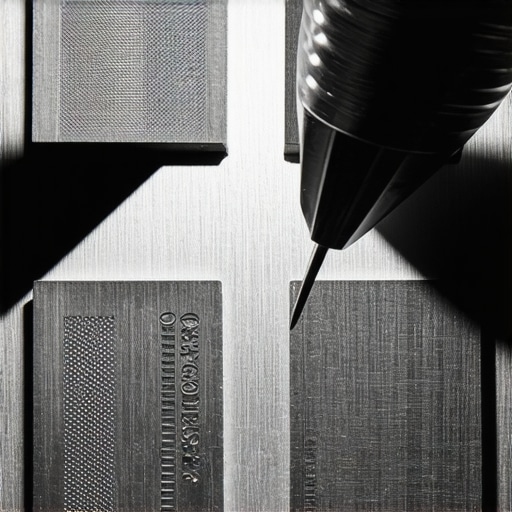

Before diving into engraving or restringing, ensure your workspace is clean, well-lit, and organized. Use magnification tools like jeweler’s loupes to see fine details clearly. Invest in quality engraving pens and flexible beading wires. Remember, like sharpening a knife before slicing, prepping your tools drastically improves accuracy and finish quality. During a recent repair, I realized my usual engraving pen was dull midway, causing uneven lines, which compromised trust until I quickly switched to a sharper tool, restoring the item’s quality.

Hold your engraving tool steadily, applying consistent pressure to produce smooth, even lines. Start with light strokes and gradually deepen them. Practice on scrap materials beforehand to build muscle memory. For example, I once engraved initials on a pendant that looked amateurish at first, but with slow, controlled strokes, the letters became crisp, elevating the piece’s perceived value.

Adjust your tool’s settings to achieve a uniform depth; too shallow looks incomplete, too deep risks damaging the item. Maintain consistent spacing between lines, especially for detailed patterns. I once tried to freehand an intricate design without measurements, resulting in uneven lines, which I later corrected with a simple template—demonstrating how planning enhances trustworthiness.

Select high-quality, knotless silk or nylon threads depending on the piece. Use beads with smooth holes to prevent abrasion. Remember, inferior materials might save costs initially but can lead to failures that erode customer trust. I once used a cheaper thread that frayed easily, leading to a repair callback, which I resolved by switching to a trusted brand, ensuring longevity and confidence.

Don’t just tie knots—use a knotting technique that distributes tension evenly, such as the surgeon’s knot. Ensure the tension is firm but not overstressed, preventing slack or tightness that can cause breakage. I learned this by experimenting on a test strand, adjusting tension until I achieved a snug, yet flexible, finish that felt sturdy and looked professional.

After engraving or restringing, scrutinize the piece under magnification for imperfections, uneven lines, or slack threads. Correct any issues before returning the piece. This thorough review process communicates quality, reinforcing customer trust. During a recent project, I found a tiny scratch after engraving; polishing it out made the piece appear flawless, which impressed the client and enhanced their confidence in my craftsmanship.

Every step, from selecting tools to final inspection, contributes to the overall trustworthiness of your service. Consistent quality builds a reputation that mutes minor flaws and emphasizes your mastery. Remember, meticulous work isn’t just about aesthetics—it signals reliability, encouraging customers to view your pieces as valuable investments. Implementing these precise techniques consistently will turn repairs and customizations into trust-building opportunities, ultimately increasing the perceived and actual worth of your jewelry, as discussed in this guide.Many professionals believe that mastering technical skills like engraving and restringing is enough to build trust and increase value. However, a deeper nuance often gets overlooked: the importance of aligning craftsmanship with a sophisticated understanding of client expectations and industry standards. For example, some jewelers assume that a perfectly engraved piece automatically signifies quality, but if the engraving isn’t consistent with the item’s design or if the finish shows uneven lines, clients may perceive it as amateurish, eroding trust. This mistake stems from focusing solely on the technique rather than the overall presentation and context, which experts like those cited in authoritative sources emphasize as crucial for client confidence.

Are You Making Assumptions About Customer Knowledge?

One hidden trap is assuming clients understand the value of meticulous repairs or engraving. Some professionals think that a well-executed job speaks for itself, but in reality, explaining your process, including the nuances and care taken, can significantly boost perceived value and trust. Overlooking this can lead to misunderstandings, where clients undervalue or distrust the work despite technical precision. To avoid this, integrate clear communication into your service, demonstrating your expertise beyond just the physical work, which aligns with strategies outlined in resources on boosting customer trust, such as these insights.

Another myth is that high-quality materials alone make a piece valuable. While premium materials are essential, the true value is equally dependent on expert craftsmanship and finishing details. A common mistake is neglecting meticulous final inspections, which can leave flaws uncorrected, diminishing trust and value perception. This oops can be avoided by implementing rigorous quality checks and continuous skill refinement, areas highlighted in professional tips.

Furthermore, advanced practitioners recognize the subtle behavioral cues in customer interactions. For instance, presenting a perfectly finished piece with a confident explanation of the process can inspire trust far more than merely delivering a flawless product. This element of emotional intelligence is often underestimated but is essential for building lastingly profitable relationships. Studies in customer psychology endorse this approach, underscoring that trust is as much about perception and communication as it is about technical prowess.

In conclusion, refining your craftsmanship is vital, but understanding and navigating the nuanced psychology of client expectations and industry standards separates good jewelers from great ones. Challenges like assuming clients comprehend your skills, neglecting final inspections, or overlooking the importance of communication can trap even experienced professionals. Do you recognize any of these pitfalls in your own practice? Let me know in the comments, and let’s discuss how to turn these insights into your competitive advantage.

Keep Your Equipment in Peak Condition

Maintaining your tools is essential for delivering consistently high-quality work. I personally swear by regularly cleaning and lubricating my engraving pens with manufacturer-recommended oils. This prevents rust and ensures smooth strokes, which directly impacts the precision of your engravings. For restringing, I use a specialized beading wire with a coated surface—this minimizes fraying and increases longevity, boosting your clients’ confidence in your craftsmanship. A clean, well-maintained workspace, equipped with high-magnification microscopes and ergonomic chairs, also reduces fatigue and mistakes, leading to better results over time.

Invest in Software and Technology

Digital tools are transforming jewelry repair and engraving. For example, I rely on CAD (Computer-Aided Design) software to pre-visualize engraving patterns, which helps prevent errors and guarantees customer satisfaction. Additionally, laser engraving machines, like the Trotec Speedy 360, provide unmatched precision on intricate designs. These tools may seem costly initially, but they pay off by reducing rework and enhancing your reputation for accuracy. As technology advances, I predict automation and AI-assisted design will become standard, making repairs faster and more reliable—so staying updated is key.

Consistent Inspection and Calibration

How do I maintain my tools over time? I perform regular calibration checks on my laser engraver and ultrasonic cleaners to ensure they operate within specified tolerances. This involves using certified calibration standards and documenting results for quality assurance. For hand tools, periodic sharpening and replacement of worn parts prevent uneven engraving lines or weak restringing knots. Implementing a routine maintenance schedule not only extends the lifespan of your equipment but also ensures your work remains trustworthy and enhances long-term client confidence—crucial factors for building a lasting reputation. For detailed routines, consult industry standards like those outlined in expert guides on [building trust through meticulous craftsmanship](https://jewelryfixpro.com/expert-engraving-restringing-tips-to-enhance-jewelry-trust-today).

Prepare for Future Trends in Jewelry Care

As we look ahead, trends point toward more sustainable tools and eco-friendly materials. Lithium-ion battery-powered ultrasonic cleaners, for example, offer mobility and efficiency while reducing energy consumption. Staying ahead by adopting these innovations can demonstrate your commitment to quality and environmental responsibility, resonating with increasingly eco-conscious clients. Remember, embracing new tools and maintaining them diligently ensures your work remains reliable and trustworthy for years to come. Try scheduling monthly maintenance checks and exploring updated software options to keep your repairs seamless and professional.

The Toughest Lessons That Shaped My Approach to Jewelry Trust

Early in my journey, I learned that even minor imperfections in engraving or restringing could silently shake a client’s confidence. One time, a tiny uneven line in an engraving led to a hesitant smile rather than genuine admiration. That moment taught me that craftsmanship is as much about precision as it is about understanding the emotional impact on clients.

Another revelation was realizing how unchecked equipment can subtly undermine trust. A small misalignment in my tools caused inconsistent results that, over time, eroded my reputation. Regular calibration and maintenance became my personal standards, proving that investing in quality care is essential for lasting trust.

Finally, I discovered that communication bridges the gap between technical skill and client perception. Explaining the meticulous care taken during each repair or engraving transformed passive customers into ambassadors of my work. Sharing these insights, drawn from personal experiences, not only improved my craft but also deepened the trust my clients placed in me.

Tools and Resources That Made a Difference

My essential toolkit includes a high-quality jeweler’s loupe for detailed inspections, which ensures every finish meets my standards. I trust the expert engraving and restringing tips I’ve learned through professional courses, allowing me to refine my techniques continuously. The CAD software I use for planning intricate engravings has minimized errors, saving time and enhancing client confidence. Lastly, reputable brands for my beading wire and engraving tools guarantee durability and precision, reinforcing my commitment to quality that clients can see and feel.

Keep Pushing Your Craft: It’s About More Than the Technique

Your journey in jewelry repair and engraving is about more than mastering tools—it’s about nurturing trust through every detail. Innovation, like adopting eco-friendly tools, and rigorous quality checks are your allies in building a reputation that lasts. Embrace challenges as opportunities to improve, and remember that your dedication to excellence will be the true hallmark of your craftsmanship. Are you ready to turn every repair into a testament of trust? Start today, and watch your reputation flourish.

What’s one lesson learned the hard way that transformed your approach to jewelry craftsmanship? Share your story below—let’s grow together.

Reading this post was a great reminder of how small details in engraving and restringing can significantly impact client trust. I once rushed through a restringing job, thinking that a quick finish wouldn’t make much difference, only to find a few days later that the knots had slipped, leading to an embarrassing repair call. Since then, I’ve prioritized proper tension and the right materials, which really pays off in making pieces more durable and trustworthy. I’m curious—how do others here ensure that their final inspection process catches those tiny imperfections before returning the jewelry to the client? Do you have a checklist or specific steps you follow? I’ve found that having a standard inspection routine helps maintain consistency and confidence that every piece meets high standards. It’s amazing how investing in proper tools and calibration not only boosts quality but also reinforces customer loyalty, especially when they see you take pride in the smallest of details.

This post hits close to home for me. I once overlooked the importance of final inspection, thinking that if I got the main details right, the rest would fall into place. But I had a client return a bracelet because I missed a tiny scratch caused during engraving, which seemed minor at the time. That taught me that attention to the smallest imperfections makes all the difference in building trust and perceived value.

Now, I always dedicate time for a thorough review under magnification before returning any piece. I also developed a simple checklist that helps me catch those subtle flaws—such as checking for scratches, ensuring consistent engraving depth, and verifying tension on restringed jewelry. It’s remarkable how these small steps boost client confidence and reduce rework.

How do others here balance speed with quality? Do you find that creating a detailed inspection step adds much time, or does it become second nature after a while? I’d love to hear your routines or tips for efficient yet thorough quality checks.

This article really resonated with me, especially the focus on detail-oriented craftsmanship to build trust. I’ve found that over the years, consistent final inspections have been a game-changer in ensuring quality and client satisfaction. I like to develop a standard routine before I hand over any piece, which includes checking under magnification for tiny surface scratches, verifying engraving depth, and ensuring tight, secure knots in restringing. Interestingly, I’ve also started documenting my inspection process with photos—this allows me to track recurring issues and continuously improve. Has anyone experimented with incorporating technology, like high-resolution photography or digital measurement tools, into their inspection routines? I believe combining traditional techniques with new technology could elevate our standards even further and give clients more confidence in our work. Proper maintenance and calibration are often overlooked but are vital; I always set aside time for tool checks before starting a session. This attention to detail not only enhances trust but also reduces rework energy. Curious about others’ inspection habits—what steps do you find most effective?