I still vividly remember the moment I realized that a tiny engraving could make or break a piece of jewelry’s value and sentimental worth. It was a small, delicate inscription I attempted myself, and it looked more like a scratch than a meaningful message. That experience taught me a crucial lesson: precision matters in jewelry repair, especially when it comes to building lasting trust with clients. If you’ve ever faced a situation where a botched repair or engraving left you doubting your skills, you’re not alone. Many professionals struggle with ensuring their work inspires confidence rather than suspicion.

The Power of Expert Skills in Jewelry Repair and Engraving

In our line of work, trust is earned through consistent quality and attention to detail. When clients hand over their most valued possessions, they expect nothing but the best. That’s why mastering techniques like engraving and restringing plays a vital role in establishing your reputation. These services aren’t just about aesthetics—they’re about creating a sense of confidence that their jewelry will stand the test of time.

Early in my career, I made the mistake of rushing an engraving, thinking a quick job was enough. The client’s disappointment was a stark reminder that shortcuts only undermine trust. Instead, investing time in honing skills—whether through detailed repair and appraisal tips or mastering custom engraving—can transform your reputation and lead to repeat business.

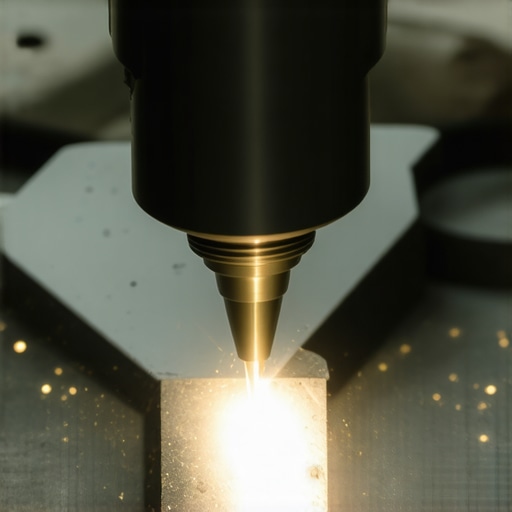

Do you recall a time when a small mistake dented your credibility? Or maybe you’ve hesitated to offer a service because of doubts about your expertise? Recognizing these moments is the first step toward improving your craft and boosting client confidence. In the next sections, I’ll share practical strategies that have helped me—and many other professionals—turn uncertainties into strengths, ensuring your clients always feel secure and valued.To achieve precise engraving, start by selecting the right tools—think of your engraving burrs as brushes in a painter’s palette, each offering unique strokes. Secure the jewelry firmly in a vice or bench pin, akin to holding a fragile leaf steady before drawing on it; this stability prevents slips and ensures accuracy. Use a jeweler’s loupe or magnifier, similar to a detective’s magnifying glass, to scrutinize minute details and correct imperfections early in the process. Practice by drawing sketches lightly with a pencil, then transfer the design onto the jewelry with a fine-point engraving pen, making sure to keep your hand steady, like a calligrapher crafting each letter. Begin with shallow lines, gradually deepening them as your confidence grows, akin to chiseling stone step by step. Always double-check measurements and spacing—think of it as a builder confirming dimensions before laying bricks—to ensure symmetry and balance in the design. When restringing, measure the length precisely with a flexible ruler or a micrometer, just as a tailor measures fabric before cutting, and select the appropriate wire gauge for durability. Thread the beads carefully, like threading a needle through fabric, ensuring they sit snugly without excessive movement. For repair work, assess the damage thoroughly, comparing it to a mechanic diagnosing a car; identify whether soldering, replacing, or reshaping is needed, then proceed methodically. Use quality solder and flux, much like a chef choosing fresh ingredients, to ensure a seamless bond. Always test the stability of your work by gently tugging or shaking the piece, akin to a quality control check in manufacturing.  Incorporate these steps into your workflow to elevate your craft—precision, patience, and practice are your best tools. For further guidance on building unwavering trust through craftsmanship, explore engraving and restringing techniques that resonate confidence. Developing your skills through consistent practice transforms craftsmanship into trust, turning clients into lifelong patrons.Many artisans believe that mastering the basic tools and techniques suffices for creating flawless jewelry engravings or repairs, but the true nuance lies in understanding the subtle intricacies that distinguish a professional job from amateur work. One common myth is that faster work equates to better craftsmanship, but rushing through delicate processes often leads to mistakes that undermine trust and quality. For example, applying excessive pressure with an engraving tool can cause uneven lines or accidental scratches, which are difficult to fix and can diminish the piece’s value. Instead, slower, deliberate strokes—similar to a calligrapher’s careful penmanship—yield more precise and elegant results, as emphasized by expert jewelers trained in meticulous techniques.

Incorporate these steps into your workflow to elevate your craft—precision, patience, and practice are your best tools. For further guidance on building unwavering trust through craftsmanship, explore engraving and restringing techniques that resonate confidence. Developing your skills through consistent practice transforms craftsmanship into trust, turning clients into lifelong patrons.Many artisans believe that mastering the basic tools and techniques suffices for creating flawless jewelry engravings or repairs, but the true nuance lies in understanding the subtle intricacies that distinguish a professional job from amateur work. One common myth is that faster work equates to better craftsmanship, but rushing through delicate processes often leads to mistakes that undermine trust and quality. For example, applying excessive pressure with an engraving tool can cause uneven lines or accidental scratches, which are difficult to fix and can diminish the piece’s value. Instead, slower, deliberate strokes—similar to a calligrapher’s careful penmanship—yield more precise and elegant results, as emphasized by expert jewelers trained in meticulous techniques.

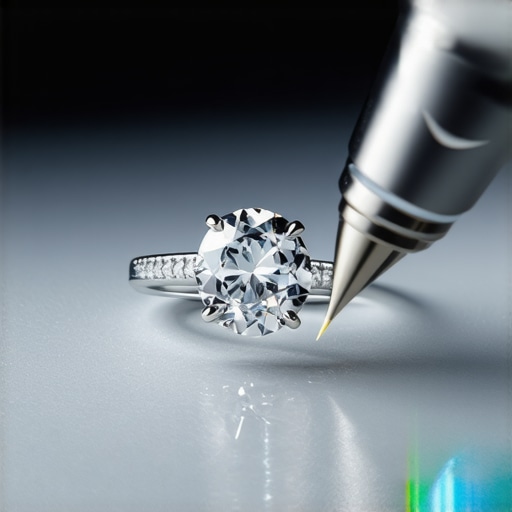

Another advanced misconception involves the assumption that all engraving or repair methods are interchangeable. In reality, each piece’s material, design, and historical significance require a tailored approach. For instance, working with vintage jewelry demands gentler soldering methods and specialized tools to prevent damage—a nuanced skill that’s often overlooked. Misjudging these factors can not only damage the jewelry but also erode the trust that clients place in your expertise.

Beyond techniques, many overlook the importance of thorough assessment during repairs and appraisal. Jumping straight into fixing a broken clasp without evaluating the underlying structural issues can lead to recurring problems. An expert’s keen eye will identify minor stress points and suggest appropriate reinforcement, ensuring longevity and sustained trust. Research indicates that attention to such details significantly increases customer confidence and enhances perceived value, as shown in studies by industry specialists.

Have you ever fallen into this trap? Let me know in the comments. Remember, advancing your skills involves more than just knowing how to use tools—it’s about understanding the complexity behind each piece and each process. Take the time to refine your approach, consider material nuances, and avoid shortcuts. The difference between good and exceptional work is often in the details others neglect, and that’s what truly builds lasting trust in the jewelry industry.Maintaining your jewelry tools and adopting precise methods are critical steps toward ensuring long-term quality and client trust. High-quality equipment isn’t just a luxury; it’s an investment that pays off through consistent results. Personally, I swear by the Foredom Dual-Speed Flex Shaft because of its versatility and durability, allowing for intricate engraving and delicate repair work with exceptional control. Its variable speed control, which I adjust meticulously during each project, ensures that I avoid excessive pressure that could damage sensitive pieces. Using a Foredom also facilitates smooth, precise cuts, making intricate designs look flawless, which is crucial in building client confidence.

For magnification, I prefer the Optivisor with a 10x lens. It provides a distortion-free view and is ergonomic for long hours of detailed work—an essential tool for examining tiny engravings or tiny fractures. Proper lighting is equally important; I recommend the OttLite Desk Lamp with adjustable brightness to prevent eye strain and ensure visibility.

When it comes to software for design or appraisal documentation, I rely on the latest version of Point of Sale (POS) apps with built-in inventory tracking and client history management. These tools streamline workflow and allow quick access to past repairs or engravings, fostering transparency and trust. As industry trend predictions lean toward integrated digital solutions, embracing such platforms positions your workshop for future growth.

How do I keep my tools performing like new? Regular maintenance is a must. I clean my flex shaft and burrs after every session, using gentle cleaning techniques—a mix of ultrasonic cleaning and soft brushes—to prevent buildup that can affect precision. Replacing worn burrs before they cause damage or uneven engraving is also vital. I recommend setting a schedule: inspect burrs weekly and replace every few months, depending on usage. Proper maintenance not only extends tool life but also maintains the quality and safety of your work.

In terms of long-term results, investing in high-end equipment paired with meticulous care ensures your craftsmanship remains reliable over years. This trust-building commitment resonates with clients, inspiring confidence that their jewelry is in expert hands. With the evolution of tools, advancements like precision engraving techniques are becoming more accessible, enabling a new level of quality in every project.

To stay ahead, integrating advanced tools into your workflow is essential. For example, trying the practice of micro-lapping with diamond-embedded burrs can create ultra-smooth finishes on intricate engravings—a technique recommended by industry veterans. Don’t wait; test this method on a scrap piece to experience the difference for yourself and elevate your craftsmanship today.

The Hardest Lesson I Learned About engraving,jewelry repair,restringing,appraisal

One of the most valuable insights came from a mistake that seemed minor at the time—a rushed engraving that resulted in uneven lines. That experience taught me that patience and attention to detail are the cornerstones of trustworthy craftsmanship, especially when working with delicate or vintage pieces that demand extra care.

Stop Overlooking Small Details That Set You Apart

I’ve realized that the difference between good and exceptional work often lies in those overlooked nuances: proper tool maintenance, precise measurement, and gentle handling. Focusing on these aspects consistently has helped me foster stronger relationships with clients who value quality over speed, ultimately building lasting trust.

The Role of Specialized Resources in Elevating Your Skills

Through my journey, I discovered that investing in specific tools and knowledge sources makes a real difference. For example, trusted equipment like the Foredom Dual-Speed Flex Shaft and magnification tools like the Optivisor have transformed my workflow. Additionally, industry-leading literature and tutorials have pushed my craftsmanship to new levels.

Trust Is Built Through Consistency and Passion

Finally, I learned that mastering techniques isn’t enough; it’s about cultivating a genuine passion for your craft and consistently striving to improve. Every piece repaired or engraved with care becomes a testament to your dedication, turning clients into ambassadors of your work. Remember, the jewelry industry rewards those who invest not just in tools but in lifelong learning and integrity.

Your Turn to Try

Are there small details or tools you’ve overlooked that could elevate your jewelry repair or engraving work? Share your experiences or questions below—let’s grow together in building lasting trust through craftsmanship!

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)