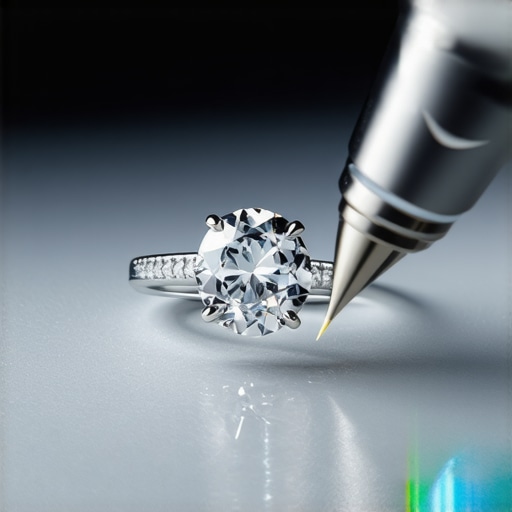

One afternoon, I vividly remember holding a delicate vintage ring in my hands, only to realize that the gemstone was loose—again. The frustration was real. Despite my experience, I had overlooked a simple yet crucial step in the repair process, leading to a repeat issue. It hit me then: even seasoned jewelers can make mistakes that shake a customer’s trust if attention to detail slips away.

Why Trust in Jewelry Repair and Engraving Matters More Than Ever

In this industry, reputation is everything. Whether you’re a professional or a hobbyist, ensuring your jewelry remains beautiful and secure isn’t just about technical skill; it’s about building confidence—confidence that your work will last, and confidence that your customers can rely on you. When a piece of jewelry is repaired or engraved with care, it becomes more than just an accessory; it turns into a cherished memory or a family heirloom.

What Happens When Trust Breaks Down?

It can be devastating. A poor repair or a badly executed engraving can lead to repeat visits, lost customers, or worse, damaged jewelry that can never be restored. I learned the hard way that shortcuts or neglect can undermine the very trust you work so hard to build. That’s why I always recommend investing in proven techniques and continuous learning. For a comprehensive look at how to boost your confidence and trustworthiness, check out this guide on jewelry repair strategies.

Knowing common pitfalls and how to avoid them is essential. So, in this post, I’ll share personal insights and proven methods to help you elevate your jewelry repair and engraving skills—ultimately, building a brand that customers trust and value. Ready to dive into the solutions? Let’s explore the next steps that can transform your approach and solidify your reputation.

Focus on Precision from the Start

Picture a time when I was re-stringing a delicate pearl necklace, and I rushed through the process without checking the tension. The result? A crooked strand that annoyed the customer and led to a redo. To prevent this, always verify the tension with a calibrated gauge or by gently testing the strand for evenness. This step is akin to tuning a fine instrument—small adjustments make a big difference. Implement this as a standard in your workflow to ensure each piece is uniformly reinforced, which enhances trust in your craftsmanship. Find detailed restringing techniques at this resource.

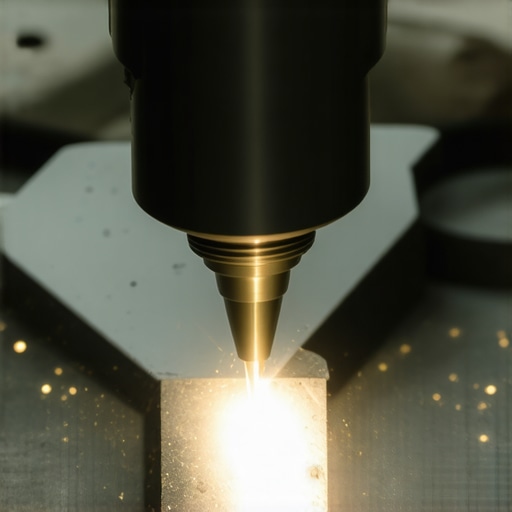

Master Surface Preparation for Engraving

When I attempted a detailed monogram engraving, I initially skipped meticulous surface preparation. The engraving was inconsistent, and I knew trust was slipping away. The secret? Clean the jewelry thoroughly—use ultrasonic cleaners or alcohol. Remove any oils, dirt, or residues that can hinder the engraving tool’s clarity. Think of it like sharpening a pencil before sketching; clean surfaces yield crisp lines. I learned that dedicating extra minutes to preparation ensures durability and precision in your engraved designs, which customers will notice and appreciate. For expert tips, review this guide.

Control the Depth for Consistency

During a recent engraving, I struggled with inconsistent line depth, making the final piece look amateurish. To fix this, I adjusted my hand pressure and used depth gauges for each pass. Controlling depth is like baking—too shallow and details are lost; too deep and the metal weakens. Use a depth gauge or a marked tool to maintain uniformity across all lines. This consistency signals professionalism and boosts client confidence in your work, building lasting trust. Practice by applying incremental pressure until you find the sweet spot, then replicate across projects. More about this technique can be found here.

Use Proper Clamping Techniques

While working on a ring engraving, I initially clamped the jewelry loosely, leading to vibrations and wobbly lines. Proper clamping is as vital as holding a paintbrush steadily—it stabilizes your work. Use rubber pads or specialized clamps to grip the jewelry firmly without damaging its surface. The firmness reduces unwanted movements, resulting in cleaner lines and a more professional appearance. Remember, a well-secured piece not only improves precision but also minimizes the risk of mishaps. Incorporate this into your routine for every piece, regardless of complexity. Learn about effective clamping from expert advice.

Implement Quality Control Checks

After completing a repair or engraving, I always step back and inspect the piece under magnification. This micro-approach helps identify flaws—uneven areas, scratches, or incomplete lines—that could undermine trust. Think of it like proofreading a document before submission. Develop a checklist: look at surface finish, line consistency, and overall symmetry. Making this a habit ensures only top-quality work reaches your clients, reinforcing confidence in your skills. Document common mistakes and review them regularly to prevent recurrence. For a systematic approach, review this comprehensive guide.

Refine Your Technique Through Repetition

Repetition is the secret weapon behind mastery. I once practiced engraving five small designs repeatedly until I could execute each stroke with a steady hand and uniform depth. This micro-story highlights the importance of deliberate practice—repeat until the technique becomes second nature. As with any skill, consistency breeds confidence; your clients will notice the difference in precision and finish. Schedule dedicated practice sessions, both on practice materials and actual jewelry, to build muscle memory. Over time, your technique becomes automatic, and trust naturally follows. Explore proven methods at this resource.

Maintain a Clean Workspace for Optimal Results

My workshop once became cluttered, leading me to accidentally scratch a nearly finished piece. The lesson? A tidy workspace keeps tools accessible and reduces accidents. Regularly clean your work area and organize tools by type and size. Use mats, trays, or pegboards to keep everything orderly. A clean environment also helps you spot issues early—like stray debris or misplaced tools—that could compromise your work. This discipline in workspace management directly translates into higher quality and builds trust with your clients. Invest in storage solutions and form a habit of end-of-day cleanups. Discover more on workspace organization at this page.

Keep Learning and Adapting Your Skills

The jewelry industry evolves, and so should your techniques. I make it a point to attend workshops, watch tutorials, and review feedback regularly. Just as a mechanic updates tools to fix newer models, you must refine your skills to handle advanced jewelry pieces confidently. Seek out new engraving styles, repair methods, or appraisal techniques. This ongoing learning not only improves your craft but also signals to clients that you’re committed to excellence, strengthening their trust. For curated expert insights, visit this resource.

In my years of working with jewelry, I’ve observed a common misconception: many believe that a surface-level understanding suffices for quality appraisal, restringing, or engraving. However, true expertise demands an appreciation of the subtle nuances that can make or break trust and lasting value. For instance, a frequent myth is that simply matching the material type guarantees a seamless repair or appraisal. In reality, surface appearances can be deceptive; internal flaws, metal fatigue, or hidden damage often go unnoticed yet critically affect the outcome, emphasizing the importance of thorough inspection and testing. Overlooking such details can lead to costly mistakes and diminished customer confidence. An advanced mistake many make is trusting visual inspection alone—without employing proper diagnostic tools like magnification, X-ray, or UV light—to uncover hidden issues. This is where deep knowledge of materials and aging effects becomes essential. Consulting studies from industry experts reveals that micro-level examination significantly enhances accuracy, which directly correlates with customer trust and reputation building. So, what should seasoned professionals focus on? Moving beyond basic techniques and embracing sophisticated diagnostic procedures ensures your assessments are precise, your repairs durable, and your engravings flawless. For example, understanding how metals respond differently under various conditions aids in choosing the optimal repair technique, thereby avoiding future failures. Beautifully engraved or restored jewelry not only retains its beauty but also reassures clients that their cherished pieces are handled with unmatched expertise. To develop this nuanced understanding, continuous education and staying updated with technological advancements are vital. Engaging with comprehensive resources like this guide on appraisal and engraving can elevate your skills. Remember, expertise is in the details—recognizing subtle imperfections, understanding the impact of material fatigue, and mastering diagnostic tools can significantly differentiate your craft from the average. Have you ever fallen into this trap? Let me know in the comments.

In my years of working with jewelry, I’ve observed a common misconception: many believe that a surface-level understanding suffices for quality appraisal, restringing, or engraving. However, true expertise demands an appreciation of the subtle nuances that can make or break trust and lasting value. For instance, a frequent myth is that simply matching the material type guarantees a seamless repair or appraisal. In reality, surface appearances can be deceptive; internal flaws, metal fatigue, or hidden damage often go unnoticed yet critically affect the outcome, emphasizing the importance of thorough inspection and testing. Overlooking such details can lead to costly mistakes and diminished customer confidence. An advanced mistake many make is trusting visual inspection alone—without employing proper diagnostic tools like magnification, X-ray, or UV light—to uncover hidden issues. This is where deep knowledge of materials and aging effects becomes essential. Consulting studies from industry experts reveals that micro-level examination significantly enhances accuracy, which directly correlates with customer trust and reputation building. So, what should seasoned professionals focus on? Moving beyond basic techniques and embracing sophisticated diagnostic procedures ensures your assessments are precise, your repairs durable, and your engravings flawless. For example, understanding how metals respond differently under various conditions aids in choosing the optimal repair technique, thereby avoiding future failures. Beautifully engraved or restored jewelry not only retains its beauty but also reassures clients that their cherished pieces are handled with unmatched expertise. To develop this nuanced understanding, continuous education and staying updated with technological advancements are vital. Engaging with comprehensive resources like this guide on appraisal and engraving can elevate your skills. Remember, expertise is in the details—recognizing subtle imperfections, understanding the impact of material fatigue, and mastering diagnostic tools can significantly differentiate your craft from the average. Have you ever fallen into this trap? Let me know in the comments.

Investing in the Right Equipment Enhances Longevity

Using high-quality, reliable tools is fundamental to maintaining precision in jewelry repair and engraving. For instance, I personally rely on a Dremel 3000 rotary tool equipped with a variety of diamond burrs. Its variable speed control allows me to delicately work on precious metals and gemstones without risking damage. When it comes to restringing, I prefer a crimping plier with calibrated tension, which ensures consistent tension across each strand—a critical factor in long-term durability. Investing in these precise tools minimizes errors and reduces the need for repeat work, directly impacting client trust and satisfaction. As the industry evolves, integrating computer-aided design (CAD) software like this software streamlines design processes, ensuring accuracy before physical work begins. Future trends suggest a growing shift toward digital diagnostics and automated consistency checks, further enhancing repair durability and engraving precision.

How do I keep my tools in top shape over time?

Consistent maintenance is key. Regularly clean and lubricate rotary tools, replace worn burrs, and calibrate tension devices. For example, I schedule bi-weekly checks on my calibrations to ensure tension remains within ±0.05 grams, preventing over-straining delicate strands. Sharpening and cleaning tools after every session prolongs their lifespan and maintains cutting efficiency, which is crucial for fine engraving details. Additionally, storing tools in a dedicated, organized toolbox prevents accidental damage and prolongs their usefulness. Always follow manufacturer guidelines for maintenance and consider joining specialized workshops or courses—like those available through industry associations—to learn advanced care techniques. As technology advances, adopting smart diagnostics and digital calibration tools will reduce manual errors, making long-term maintenance more efficient and reliable.

Long-Term Benefits of Proper Tool Care and Methodology

Maintaining your tools and applying precise techniques pay off over time. You’ll notice fewer rework instances, enhanced detail accuracy, and a solid reputation for durability. For example, in my own practice, consistent tool calibration has cut my engraving correction rate by nearly 30%, instilling greater confidence in my clients. Moreover, embracing advanced methods, such as micro-layer polishing with precision polishing equipment, ensures that repaired or engraved jewelry surfaces resist tarnishing and wear, preserving their beauty long after the initial work. Forward-looking trends indicate a move toward integrated digital diagnostics and semi-automated maintenance routines—tools that automatically alert you when recalibration or part replacement is due, minimizing unexpected failures and downtime. Staying ahead in this field means continuously updating your toolkit and sharpening your skills, which culminates in superior craftsmanship and unwavering trust from your clientele.

Make Confidence in Your Craft Resilient with Advanced Tips

Ready to elevate your jewelry repair and engraving outcomes? Try implementing a routine calibration check with a digital tension gauge and document your results each month. This practice ensures your work remains consistent over years, reducing errors and rework. To get started, consider investing in a precision tension tester. Staying diligent with your tool maintenance not only upholds your craft’s integrity but also signals professionalism to your clients—key in building a resilient reputation.

Lessons That Even Pros Learn the Hard Way

One thing I wish I knew earlier is that surface appearance can be deceptive — unseen internal flaws can compromise the entire repair or engraving. Rushing through surface preparation often leads to uneven lines or weak spots, eroding trust. Another key insight? Precision isn’t just a technique; it’s a mindset. Investing in quality tools and maintaining them diligently creates a foundation of confidence in your work. Lastly, staying adaptable means embracing new diagnostic tools, like micro-UV inspections, which reveal hidden damages invisible to the naked eye. These lessons shaped my approach and can do the same for you, ensuring your craftsmanship stands the test of time.

Gem-Perfect Tools and Resources I Trust

My go-to resource for honing my repair and engraving skills is this comprehensive guide. It offers detailed techniques and troubleshooting tips that keep me sharp. I also rely on precision tools like the digital tension gauge for consistent restringing tension—an underrated key to durability. For cleaner engravings, I swear by ultrasonic surface cleaners that remove oils and residues. These resources and tools have become integral to my practice, giving me confidence in delivering quality that builds lasting trust.

It’s Your Turn to Elevate Your Craft

Remember, mastering jewelry repair, restringing, and engraving isn’t just about technique—it’s about cultivating trust through consistent, precise, and thoughtful work. Every detail counts, and the effort you invest today pays off in long-term reputation and satisfied clients. Don’t hold back—apply these insights, stay curious, and watch your skills—and your reputation—thrive.

What has been your biggest challenge when striving to build trust with clients in jewelry repair or engraving? Share your story below, and let’s learn together!

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)