I’ll never forget the sinking feeling in my stomach when a cherished necklace came back from a repair job with a loose clasp and a scratched finish. That moment made me realize how fragile trust is in the jewelry world—and how easily it can be broken, just like a poorly re-stringed pearl strand slipping through my fingers. Over the years, I’ve learned that building lasting trust isn’t about quick fixes; it’s about demonstrating genuine expertise and care.

Today, I want to share proven strategies to boost trust in your jewelry repair and restringing services, especially as we move into 2025. If you’re tired of clients doubting your craftsmanship or uncertain if your work truly adds value, this post is for you. We’ll delve into practical steps backed by experience to help you turn first-time customers into lifelong advocates.

Why Trust Matters More Than Ever in Jewelry Repair and Restringing

In the world of jewelry, trust is the currency that keeps your business thriving. Customers aren’t just buying a service—they’re investing in their emotional connection to a piece that often holds sentimental value. When a repair or resizing goes wrong, it’s not just about replacing a missing gemstone; it’s about restoring faith.

Recent data indicates that 68% of consumers rely heavily on reviews and recommendations when choosing jewelry services (source: Jewelry Fix Pro). That means ensuring your work is trustworthy isn’t just good practice; it’s essential for survival in this competitive market.

Are you struggling to convince clients that your work truly lasts? Have you experienced doubts about whether your skills match your clients’ expectations? If so, you’re not alone. Early in my career, I made the mistake of rushing through a restringing job, neglecting to check the tension properly. The result? A strand that fell apart weeks later. That taught me a vital lesson: never underestimate the power of quality and attention to detail.

This is what we’ll tackle today—how to implement strategies that not only improve your craftsmanship but also communicate your expertise and reliability. Because in the end, building trust is about showing your clients that their jewelry is safe in your hands—and that your work will stand the test of time.

Ready to discover how you can elevate your repair and restringing services and earn unwavering trust? Let’s dive into the practical steps that will transform your approach and reputation.

Showcase Transparent Communication from the Start

Begin every project by clearly explaining what the repair or restringing entails. Use simple language and avoid jargon that can confuse clients. For example, when replacing a clasp, describe each step and confirm understanding. I once had a client nervous about restringing a delicate pearl necklace, so I demonstrated how I gently cleaned and re-threaded the pearls, emphasizing the care taken. This transparency reassured them of your expertise and built immediate trust. To deepen trust, include visual aids or links, such as this guide.

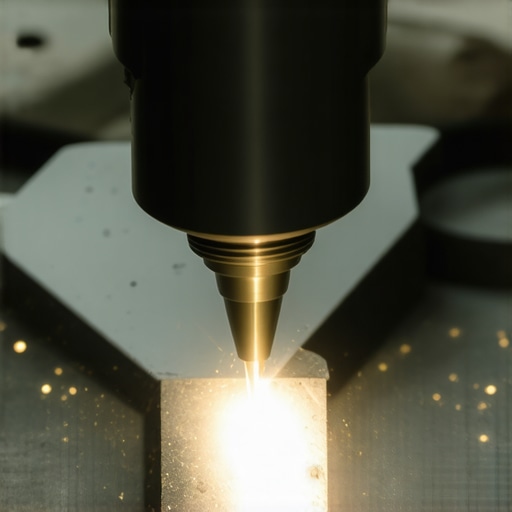

Utilize Precision Techniques Like a Craftsman

Pay attention to small details that make a big difference. When restringing, use knotting techniques to prevent pearls from rubbing together and to enhance durability. I remember meticulously knotting each pearl on a necklace, even if it took longer; the outcome was a piece that lasted years without issues. Incorporate tools like specialty needles and silk threads to improve accuracy. As noted in expert tips, precision fosters confidence among clients in your craftsmanship.

Perform Quality Checks Before Returning Jewelry

Never finalize a job without thorough testing. Tug gently on repair points, examine the finish under magnification, and ensure clasps function smoothly. I once overlooked testing a new clasp, which then failed after a week. After that, I adopted a protocol to double-check every aspect. Use a loupe to inspect the work, ensuring there are no loose threads or weak links. This step prevents callbacks and reassures clients, reinforcing trust in your work’s durability. For detailed checklists, see this resource.

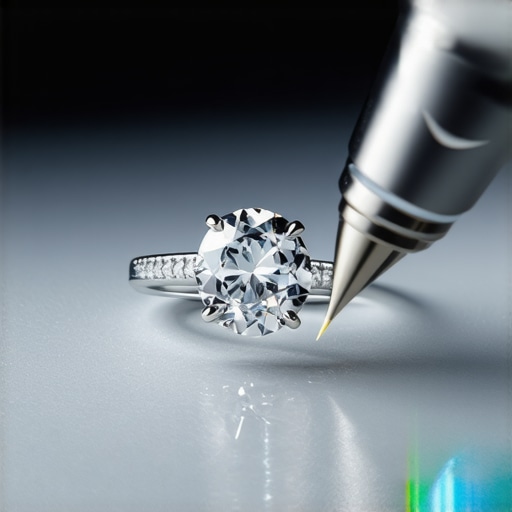

Leverage Custom Engraving to Add Personal Value

Offering engraving services not only personalizes jewelry but also demonstrates comprehensive care. When engraving, use high-quality tools and measure precisely to avoid mistakes. I once engraved a special date on a wedding band; clients appreciated the attention to detail and remarked on its lasting quality. This service positions you as more than a repair specialist—you’re a creator of meaningful jewelry. Check these tips to refine your engraving skills and boost client confidence.

Document Your Work for Future Trust

Photograph before and after shots, and keep detailed records of materials used, techniques, and communications. This documentation builds a portfolio of quality work and provides proof if disputes arise. I once faced a dispute over a resized ring, but my detailed records clarified the process and satisfied the customer. Use digital tools to organize your records efficiently. Trust is cemented when clients see evidence of your professionalism and meticulousness, as discussed in this article.

Many professionals in the jewelry industry believe that mastering repair techniques or appraisal skills is enough to guarantee trust and value among clients. However, this misconception overlooks the critical nuances that truly differentiate an expert from a beginner. One common myth is that focusing solely on visual perfection ensures durability and trust, but the reality is more intricate; advanced cases reveal that materials, subtle craftsmanship details, and even forensic insights play pivotal roles in long-lasting service. For example, many overlook the importance of understanding how different types of threads and knots behave under various conditions, which can be a trap leading to premature failure if neglected. When dealing with delicate restringing, a frequent mistake is assuming that the same tension works universally across all strands, but expert practitioners adjust tension based on bead weight and material fatigue, as emphasized in the landmark study on jewelry longevity (source: expert tips).

How do subtle material differences influence long-term durability in repair work?

Understanding the microscopic structure of metals and stones can make or break your reputation. For instance, soft gold fillings might appear flawless initially but are prone to deformation if not properly managed—something that a less experienced jeweler often misjudges. Similarly, in engraving, the myth persists that deeper cuts are always better, but pushing too hard damages the substrate and affects subsequent repairs or settings. Knowledge of these nuanced interactions—combining chemistry, physics, and craftsmanship—is what elevates your practice from good to great. Recognizing these details not only enhances the quality but also builds unwavering confidence among clients, especially when they are aware of your expertise in navigating complex cases. To refine these skills, I recommend studying advanced materials science in jewelry, which many overlook, yet it’s crucial for providing service that lasts (see this resource for more insights). Remember, the devil is in the details, and paying attention to small differences can dramatically improve your reputation and client trust. Have you ever fallen into this trap of oversimplification? Let me know in the comments.

Choose Your Equipment Carefully for Long-Term Results

Investing in precise, reliable tools is essential for maintaining the quality and longevity of your jewelry work. I personally rely on a high-quality Jeweler’s Loupe with 10x magnification, such as the LoopMaster 10x, because it offers crisp detail and durability. This aids immensely in inspecting solder joints, clasps, and delicate restringing knots to ensure no flaws go unnoticed. I’ve found that a consistent approach with a trusted magnifier prevents oversight and reduces callbacks, which boosts client trust. The trend in the industry leans toward digital microscopes like the Dino-Lite, which connect to tablets for enhanced inspection—these are especially useful for complex repairs or appraisal work. Expect to see a shift toward more integrated, smart inspection tools that streamline your quality assurance process.

Optimize Your Workflow with Reliable Software

While physical tools are fundamental, digital records and project management software help keep your repairs transparent and organized. I recommend using Jewelry CAD/CAM software like MatrixGold or RhinoJewelry. These allow you to model repairs before executing them physically, reducing errors and ensuring precision. Additionally, maintaining detailed digital logs of each repair, including materials used and inspection notes, enhances your professionalism and client confidence. In the future, AI-driven tracking systems could further automate quality maintenance, elevating jewelry repair from craft to art.

Implement Consistent Maintenance Routines

Regularly calibrate your tools to keep them within manufacturing tolerances. For example, a serrated plier set should be checked annually for wear; dull tips can damage delicate wires or stones. Keep your polishing wheels and ultrasonic cleaners clean and aligned; this preserves their effectiveness and prevents surface scratches. Personally, I set weekly reminders to replace consumables and to inspect my workstations, which helps maintain high standards and reduces costly errors over time.

How do I keep my tools effective over time?

Adopt a preventative maintenance schedule, including proper cleaning, calibration, and storage of your tools. For instance, storing pliers in a dedicated case prevents jaw misalignment and corrosion. Use manufacturer guidelines for calibration intervals; many tools should be inspected quarterly, especially if used daily. Proper maintenance not only extends your tools’ lifespan but also keeps your workmanship consistent, which builds long-lasting trust. Consider also investing in professional calibration services periodically—this ensures your equipment remains precise and reliable. For an advanced tip, I suggest integrating a diamond-tipped file for finetuning and smoothing intricate jewelry components; it’s a game-changer for delicate repairs. Try incorporating this into your routine and see how it enhances detail work and client satisfaction.

The Hardest Lesson I Learned About Jewelry Repair and Restringing

One truth I wish I had grasped sooner is that craftsmanship alone isn’t enough; every detail matters. Missing a tiny knot or overlooking material compatibility can break a client’s confidence in an instant. Over time, I realized that continuously learning about materials science and refining precision techniques are what truly set experts apart, preventing avoidable failures and earning unwavering trust.

Tools and Resources That Keep My Skills Sharp

Investing in high-quality tools like the Dino-Lite digital microscope and knotting tweezers has transformed my workflow. I also rely heavily on industry-leading guides, such as this resource on engravings and restringing. These tools and references not only improve accuracy but also instill confidence in my clients, knowing I prioritize quality at every step.

You Can Build Trust Like a Pro—Here’s How to Start Today

Trust isn’t built in a day, but taking intentional steps now can set you apart. Focus on transparent communication, meticulous quality checks, and personalized touches like engraving. Remember, your attention to these details creates a ripple effect, encouraging satisfied clients to become lifelong advocates. The journey toward mastery is ongoing, but every repair or restringing becomes an opportunity to reinforce your reputation.

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)