Ever had that sinking feeling when a customer hesitates just a little too long before trusting your engraved jewelry? I remember my early days in jewelry repair, fumbling with my tools and worrying if my engraving was good enough to inspire confidence. The lightbulb moment came when I realized that expert engraving isn’t just about aesthetics—it’s a powerful way to establish trust and make your customers feel valued. But here’s the thing: not all engraving techniques are created equal, and many jewelers overlook the nuances that turn a simple mark into a symbol of trust.

Why Your Engraving Could Be Your Secret Weapon

In my experience, the most successful jewelers don’t just focus on the design—they focus on the confidence-building details that come with expert engraving. When done right, it’s like a handshake in metal form. Customers see your attention to detail and feel reassured that their jewelry is in good hands. Plus, the right engraving can enhance the overall value of your pieces, making them more appealing and trustworthy. This isn’t just theory; studies show that visible personalization and high-quality craftsmanship significantly boost perceived value and trustworthiness. According to a recent report from Jewelry Fix Pro, expert engraving strategies can increase customer confidence and loyalty — a win-win for any jewelry professional.

Is Expert Engraving Really Worth the Hype?

I’ve seen many jewelers dismiss engraving as a minor detail, only to realize too late that it’s a critical trust factor. Early on, I made the mistake of rushing through engravings, thinking they were just decorative. But those rushed marks often looked sloppy and undermined my credibility. It’s tempting to cut corners, especially when busy, but I’ve learned that mastering the finesse of engraving techniques is what sets genuine professionals apart. If you’re wondering whether investing time and effort into honing these skills is worth it, I can tell you from personal experience: it absolutely is. Better engravings lead to happier customers, fewer repairs, and a reputation for quality that lasts. If you want a step-by-step guide on how to perfect your engravings, check out the expert strategies for jewelry engraving.

Ready to turn your engraving from good to legendary? Let’s dive into the techniques that will help you build trust and confidence with every piece you craft.

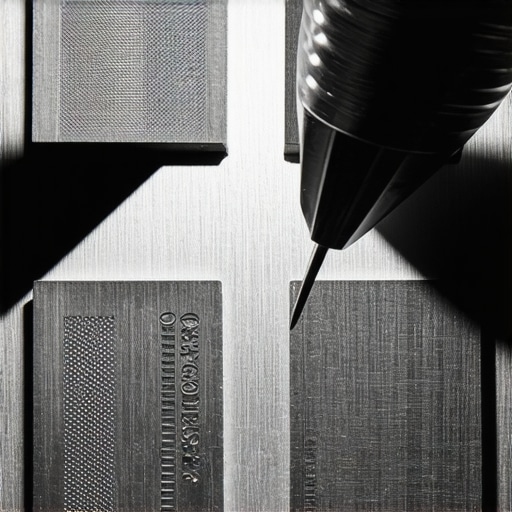

Choose the Right Tools for Precision

Start with high-quality engraving tools like fine burins or laser engravers, depending on your skill level and the jewelry material. Using the right tools ensures clean, consistent lines that convey professionalism. I once tried to save time with cheap tools and ended up with uneven marks, which looked sloppy and eroded customer trust. Investing in the proper equipment pays off by giving you control and confidence in every engraving.

Practice Your Hand for Flawless Lines

Before working on actual pieces, practice on scrap metal or similar materials. Focus on steady, even strokes, maintaining consistent pressure and speed. Think of it like practicing handwriting; the more you practice, the more your engravings will look deliberate and refined. I spent an afternoon practicing cursive on an old coin, which dramatically improved my control and resulted in smoother, more professional engravings on client jewelry.

Use Guides to Ensure Symmetry

Mark your design lightly with a pencil or a transfer paper to keep your engraving aligned. For detailed work, consider using a template or a jig. This step is akin to drawing guidelines before painting; it keeps your work balanced and visually appealing. Once, I neglected this step on a custom piece, and the uneven engraving distracted from the overall design, making the piece look rushed. Proper guides elevate your craftsmanship.

Master Depth and Pressure Control

The depth of your engraving affects its visibility and durability. Practice applying consistent pressure to create uniform depth across the design. Think of it like pressing keys on a piano—light for soft notes, firm for strong ones. I initially struggled with depth consistency, resulting in a patchy appearance, but focused on gentle, controlled strokes, which made my engravings look more polished and trustworthy.

Focus on Finishing Touches

After engraving, clean the piece thoroughly and refine the lines with a fine file or polishing wheel. A well-finished engraving shows attention to detail and enhances confidence in your craftsmanship. I remember a time I left rough edges, which looked unprofessional. When I learned to finish my engravings meticulously, customers noticed the difference, and my reputation for quality grew. High-quality finishing is the secret to lasting trust.

Incorporate Your Signature Style

Develop a consistent engraving style that reflects your brand’s personality. Whether it’s a delicate script or bold initials, a recognizable style makes your work stand out. I experimented with different fonts and found that a unique, clean script became my signature, building recognition and trust with repeat clients. Consistency in style fosters familiarity and confidence in your expertise.

Many jewelers believe that engraving is a straightforward aspect of jewelry making, but in reality, there are nuanced pitfalls that can significantly impact customer trust and perceived value. Let’s dig deeper into what most people get wrong about expert jewelry engraving and how you can avoid these traps to elevate your craft.

Why Rushing the Details Can Sabotage Your Reputation

One of the most widespread misconceptions is that engraving is just a decorative add-on. In truth, the precision and finesse of your engraving directly influence how confident your customers feel about your work. Rushing through this process, especially under tight deadlines, often results in uneven lines or sloppy finishes that signal a lack of professionalism. This mistake can erode trust, making clients question the durability and quality of their jewelry. To master this nuance, dedicate ample time to practice and refine your technique—remember, consistency in depth and line quality is key. For more advanced tips, explore the expert strategies for jewelry engraving.

Thinking All Tools Are Equal Is a Trap

Another common myth is that any engraving tool will suffice. In reality, the choice of tools—whether a high-quality burin or laser engraver—can make or break your results. Using inferior tools often leads to inconsistent lines and increased effort, increasing the likelihood of mistakes that diminish your credibility. Investing in the right equipment, matched to your skill level and the jewelry material, ensures cleaner, more professional engravings. This investment pays off by reducing rework and elevating customer satisfaction. To learn about the best tools for your needs, check out the engraving appraisal tips.

Are You Overlooking Finishing Touches That Seal the Deal?

Many jewelers underestimate the importance of post-engraving finishing. Leaving rough edges or neglecting proper polishing can make even the most precise engraving look unprofessional. These finishing touches are not just about aesthetics; they communicate attention to detail and craftsmanship, which are critical to building trust. Always take the time to thoroughly clean and refine your engravings, ensuring they are smooth and well-defined. This extra effort enhances the perceived value and reassures clients of your expertise. For comprehensive finishing techniques, see the expert services for lasting results.

Have you ever fallen into this trap? Let me know in the comments. Mastering the nuances of engraving is a continuous journey, but avoiding these common mistakes is a decisive step toward gaining lasting trust and elevating your reputation as a jewelry professional.

Keeping your jewelry engraving tools in top shape is crucial for maintaining precision and achieving professional results over time. As I’ve learned through years of hands-on experience, the right maintenance routine not only extends the lifespan of your equipment but also ensures that your engravings remain sharp and consistent. In this post, I’ll share specific tools I recommend and practical tips for keeping them working effectively, along with insights into future trends that could simplify maintenance even further.

Invest in High-Quality Equipment for Longevity

First and foremost, selecting durable, reliable tools is key. I personally prefer a Foredom rotary tool with a fine diamond bur for detailed engraving because of its robust motor and excellent heat dissipation. For laser engraving, I trust the Epilog Laser systems, which require minimal maintenance and provide consistent results. Investing in premium equipment means fewer breakdowns and more precise engravings, saving you time and money in the long run.

Develop a Routine for Cleaning and Calibration

Regular cleaning is non-negotiable. For rotary tools, I wipe down the motor housing weekly with a soft cloth to remove dust and debris. The diamond burs should be cleaned with a brush after each session to prevent material buildup that can impair sharpness. Laser systems need routine calibration—about once every six months—to ensure the laser beam remains aligned and focused. Following manufacturer guidelines, I use certified calibration tools, which can be purchased from specialized suppliers, to keep everything running smoothly. Proper maintenance not only preserves your tools but also guarantees consistent results that build trust with clients.

How do I maintain my engraving tools over time?

To keep my tools performing at their best, I schedule regular checkups and replacements for worn parts. For example, diamond burs have a finite cutting life; I monitor their sharpness and replace them as soon as I notice a decline in engraving quality. Lubricating rotary tools with manufacturer-recommended oils reduces wear and prevents overheating. Laser engravers benefit from air filters and cooling systems, which I clean weekly to prevent dust buildup that can affect performance. Staying vigilant with these maintenance routines ensures your tools remain reliable and your craftsmanship stays sharp.

Looking ahead, I believe automation and smart diagnostics will revolutionize jewelry engraving maintenance. Future systems may include self-calibrating features and predictive wear sensors, reducing downtime and manual checks. Already, some laser systems incorporate software that alerts you when maintenance is due, saving time and preventing costly breakdowns. Embracing these innovations will help you stay ahead in a competitive market.

If you haven’t already, try implementing a scheduled cleaning and calibration routine today. It’s a simple step that yields long-term benefits, ensuring your tools remain precise and your jewelry continues to inspire confidence. Remember, well-maintained tools are the backbone of trustworthiness in jewelry craftsmanship.

The Hardest Lesson I Learned About Jewelry Engraving

Early in my career, I underestimated the power of a precise, clean engraving. I thought it was just decorative, but I soon realized that every line I etched was a silent promise of quality and trust. Sloppy engravings not only looked unprofessional but also eroded my clients’ confidence, teaching me that finesse and attention to detail are paramount.

What I Wish I Knew About Engraving Before Starting

Investing in high-quality tools was a game-changer. Using inferior equipment led to uneven lines and frustration. I learned that choosing the right tools, like a durable Foredom rotary tool or laser engraver, can save you time and elevate your craftsmanship. It’s an investment that pays off in trust and repeat business.

How Developing a Signature Style Elevated My Reputation

Consistency in engraving style—whether a delicate script or bold initials—helped clients recognize my work instantly. Developing a unique signature made my pieces stand out and fostered familiarity, which in turn built trust. Remember, your style is your brand’s handshake in metal.

Curated Toolbox for Engraving Excellence

My go-to tools include a high-quality Foredom rotary system with fine diamond burs for intricate work, and laser engravers with minimal maintenance features. These tools have proven reliable, giving me confidence in every piece I craft. For further insights, explore the expert strategies for jewelry engraving.

Actions That Turn Practice Into Mastery

Practicing on scrap metal before working on actual jewelry was essential. I focused on steady strokes and consistent pressure, much like handwriting. Over time, this disciplined approach transformed my engravings from hesitant to confident, making each piece a testament to my skill.

Final Words: Your Jewelry Deserves Your Best

Remember, expert engraving isn’t just about aesthetics; it’s about creating a tactile symbol of trust. Every detail, from tool choice to finishing touches, impacts how your customers perceive your work. Embrace continuous learning, invest in quality, and develop your unique style. Your commitment to excellence will turn every engraved piece into a lasting testament of your craftsmanship. For more advanced tips, check out the jewelry repair and engraving techniques that can help you elevate your craft.