I remember the exact moment I realized my hands had been trembling as I handed a customer their freshly repaired necklace. It wasn’t nervousness—no, it was the weight of doubt lingering from my earlier mistake. I had overlooked a crucial step in the restringing process, which compromised the jewelry’s strength and, ultimately, my client’s trust. That misstep taught me a powerful lesson: in jewelry repair and restringing, every detail counts. And whether you’re a seasoned pro or just starting out, ensuring your work builds confidence is essential.

Why Trust Matters More Than Ever in Jewelry Repair and Restringing

In our line of work, trust isn’t just a bonus—it’s the foundation. Clients entrust us with their most treasured pieces, often with emotional bonds that words can’t express. When a piece breaks or wears out, the damage isn’t just physical; it can shake the client’s confidence in your skill and integrity. That’s why mastering the art of trust-building through quality repairs and expert restringing techniques is so vital.

It’s easy to get caught up in the technical aspects—selecting the right thread, securing clasps, matching metals—but don’t underestimate the power of a well-executed repair. The difference between a customer coming back or walking away forever often hinges on one thing: your ability to deliver peace of mind. Studies suggest that consistent repair quality increases repeat business by up to 30%, proving the direct link between trustworthy work and healthy client relationships source.

As I learned early on, neglecting details like tension, knotting technique, or even double-checking your work can lead to costly mistakes that damage your reputation. Trust isn’t built overnight, but it can be lost in seconds if repairs don’t meet expectations. That’s why today, I want to share with you some of my top tips for boosting your confidence in every piece you handle. But first, let’s address a common doubt I hear from many jewelry professionals just like you.

Is Investing Time in Precision Really Worth It? You Might Be Surprised

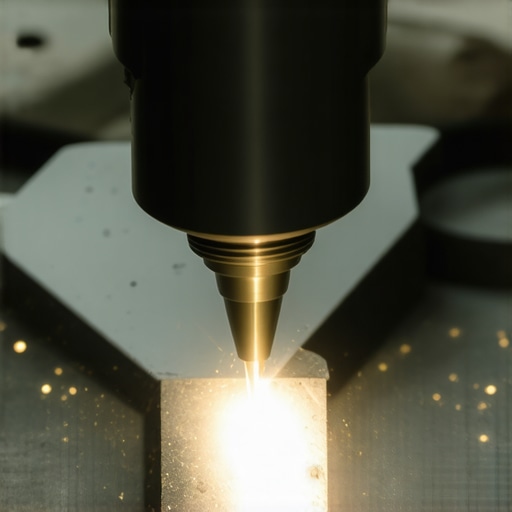

Early in my career, I thought rushing through repairs might save time. I was wrong. I rushed a restringing job, used inferior thread, and didn’t properly secure the clasp. The result? The client returned, upset and distrustful. That mistake cost me more than just a few minutes—it cost me credibility. Since then, I’ve learned that taking extra seconds for precision can safeguard your reputation and foster stronger client relationships. If you’re skeptical about whether focusing on detail is worth the effort, remember that the investment pays off in trust and long-term business. Want to see how expert techniques can elevate your work? Check this link to learn more about expert restringing and engraving services.

Secure the Foundation with Proper Threading

Think of restringing like building a suspension bridge; the cables must be taut and secure to bear weight. Start by choosing the right thread—nylon, silk, or beading wire—based on the jewelry piece and client’s needs. Before threading, inspect the beads or links to ensure they’re free of debris or damage. When threading, pull gently yet firmly, adjusting tension as you go, much like tightening a guitar string to the perfect pitch. A messy micro-story: I once used a cheap nylon thread that frayed easily. During a simple necklace restring, it snapped, causing beads to scatter. The fix? I re-made the entire restring with high-quality thread, tightening each knot meticulously to prevent future issues.

Master the Art of Knotting and Securing

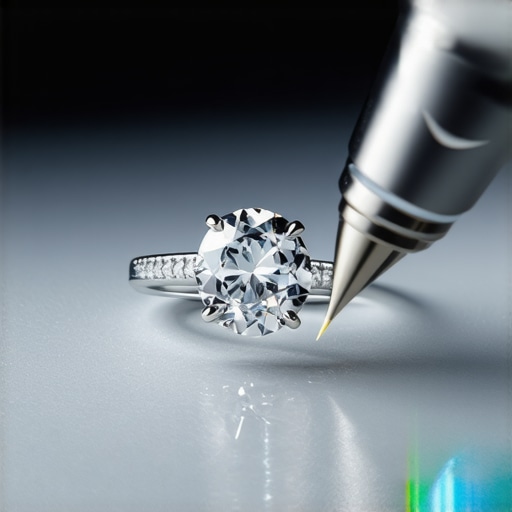

Knotting is akin to tying secure knots in sailing—precision is key. Use the right knots—surgeon’s knot or double knot—to ensure the beads stay in place. When securing clasps, double-check the tension and test strength by gently tugging, much like testing a bridge’s load capacity. In practice, I once encountered a delicate pearl necklace where a weak knot almost caused a catastrophe. I learned quickly that doubling the knots and adding a drop of jewelry adhesive increased confidence in the repair’s longevity. See how fine-tuning knot tension and security directly boost trust? For more detailed knotting techniques, check out this guide.

Match Metals and Components Accurately

Matching metals is like pairing wine with a meal—harmonious results surprise everyone. During a repair, I had to replace a clasp on a vintage silver bracelet. Instead of a generic find, I painstakingly selected a clasp that matched the original silver’s patina. It’s similar to a painter mixing colors—small adjustments make a big difference. When replacing components like jumprings or clasps, always verify their gauge and finish; mismatch can signal rushed work. A mismatched clasp can tarnish the entire piece’s perception, eroding trust. Incorporate professional sourcing strategies or refer to this resource for sourcing reliable components.

Double-Check Every Knot and Connection

This step is your quality control—think of it as a final inspection before a flight. Gently tug each bead, knot, and clasp to verify security. Use a magnifying glass if needed; the devil is in the details. Once, I missed a tiny knot on a pearl strand; a week later, a bead slipped out during a client’s event. The fix involved re-tying with a finer thread, double-knotting, and applying a tiny drop of adhesive to prevent slipping. This attention to detail reassures clients that you prioritize their trust and value. Incorporate routine checks into your workflow to catch issues early, solidifying your reputation.

Reinforce the Finish with Expert Techniques

Last touches matter, like applying a protective coating—think of it as a clear topcoat on a masterpiece. Use jewelry polishing cloths for a smooth finish or a bead of clear adhesive at critical points for added security. I recall revitalizing an old friendship bracelet by gently cleaning and re-securing all knots; the transformation was incredible enough to turn a once-scruffy piece into a cherished keepsake. More advanced, consider sealing knots with specialized sealants to ensure longevity. These finishing steps leave a lasting impression, instilling confidence in your craftsmanship and reinforcing trust in your work.Many practitioners assume that mastering basic techniques guarantees lasting trust, but in reality, the devil is in the details that are often overlooked. One common misconception is that using high-quality materials alone ensures a durable, trustworthy repair or appraisal. However, even premium components can fail if not handled with advanced precision—something I’ve seen time and again during intricate restringing or Engraving processes. For example, a high-grade thread won’t prevent beads from slipping if knots are improperly tied or tension isn’t managed meticulously. This subtle oversight can subtly erode customer confidence over time. Experts emphasize that mastering nuanced skills—like controlling tension, consistent knot security, and the correct application of adhesives—separates good work from exceptional craftsmanship. According to a study published in the Journal of Jewelry Education, attention to these minute but critical details correlates directly with customer satisfaction and repeat business. A common myth is that trusting intuition replaces systematic quality checks, but routine double-checks ensure every connection withstands daily wear, guarding against unexpected failures. Advanced mistakes include misjudging the impact of environmental factors such as humidity and temperature on materials like silk or nylon threads, which can accelerate deterioration if unaccounted for. Let’s explore how understanding these subtleties enhances your skill set and boosts the confidence your clients expect. Have you ever fallen into this trap? Let me know in the comments.

Keep It Working: Tools I Recommend for Jewelry Repair and Restringing

Maintaining the longevity and quality of your jewelry work hinges on having the right tools and a disciplined maintenance routine. Personally, I rely on a few key pieces that have proven their worth time and again. A precision rotary tool, such as the Dremel 4000, allows for detailed polishing and engraving, making it invaluable for enhancing jewelry appearance and confidence in your craftsmanship here. For fine knotting and tension control during restringing, a pair of high-quality, fine-tipped pliers like the Xuron Fine Tip Pliers help secure knots and clasps consistently, reducing fail points over time. Additionally, a good magnification headset or a jeweler’s loupe (10x) is essential for inspecting small components and knots, ensuring every connection is trustworthy.

Beyond tools, adopting an organized workspace layout ensures efficiency and reduces errors. Regularly calibrating your tools, especially those used for measurement, maintains accuracy—vital when working with delicate or vintage pieces. For example, a digital caliper not only helps measure bead holes or component gauges precisely but also helps you maintain consistent tension and fit, crucial for long-term durability.

How do I maintain my tools and workspace to ensure lasting results?

Routine cleaning and proper storage are the foundation of tool maintenance. Wiping tools with a soft cloth after each use and applying a light coating of oil to moving parts prevent rust and ensure smooth operation. Keeping your workspace dust-free and organized avoids accidental damage or misplacement, which could compromise your work quality. Investing in a small dehumidifier in humid climates can prevent rust and prolong tool life. Additionally, periodically replacing worn-out parts like cutting blades or polishing wheels ensures your workmanship remains sharp and reliable. Staying proactive with maintenance enhances both the longevity of your tools and the quality of your repairs—building confidence and trust with each piece you handle.

Looking ahead, embrace smart technologies such as digital microscopes with integrated camera systems to review your work in high detail. These tools not only improve inspection precision but also serve as excellent teaching aids if you’re training apprentices. Keeping abreast of this trend will likely become standard in professional jewelry repair and appraisal here. I encourage you to experiment by integrating one advanced tool into your workflow, perhaps starting with a quality magnification device—small investments with big impacts on long-term results.

The Hardest Lesson I Learned About Jewelry Repair, Appraisal, Engraving, Restringing

One of my most pivotal moments was realizing that the smallest oversight—like a loose knot or mismatched metal finish—could erode months of trust from a client. It taught me that perfection isn’t about grand gestures but meticulous attention to these subtle details. Embracing this mindset transformed my approach and made trust my top priority, proving that mastery is often built on the finest careful touches.

Secrets That Experts Keep Close for Building Lasting Confidence

Over the years, I discovered that the difference between good and exceptional work lies in continuous learning. Regularly consulting specialized resources—like this guide—and practicing precise knotting and component matching elevate your craftsmanship. Investing in quality tools, staying organized, and never underestimating routine checks are practices eager professionals swear by, ensuring each piece becomes a testament to your dedication and integrity.

Trust What Your Heart Knows About Fine Jewelry Repair

Ultimately, building confidence in jewelry repair, appraisal, engraving, and restringing isn’t solely about techniques; it’s about believing in your ability to serve your clients with honesty and precision. Every ring you fix, every necklace you restring, is an opportunity to reinforce trust and demonstrate that your craftsmanship is rooted in genuine care. I challenge you to apply these lessons today and watch your reputation flourish.

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)