It happened when I was halfway through restringing my grandmother’s delicate pearl necklace. I was eager to restore its original luster but ended up with a tangled, frayed mess. That moment was a lightbulb moment for me—realizing how crucial proper expert techniques are in jewelry repair. I felt a surge of frustration and doubt, questioning whether I could trust anyone to handle such treasured pieces. If you’re like me, you know the anxiety of handing over your jewelry and hoping it won’t come back less than perfect.

Why Trust Matters More Than Ever in Jewelry Restoration

In the world of jewelry repair, trust is everything. Your pieces often hold sentimental value, family history, and sometimes significant monetary worth. Yet, many people approach repairs with skepticism, fearing subpar work or worse—damage that can’t be reversed. As I learned through my early mistakes, rushing or attempting DIY fixes without proper knowledge can lead to irreversible harm. That’s why mastering techniques like expert re-stringing and engraving is vital—skills that rebuild confidence and ensure your jewelry’s longevity.

Is All Jewelry Repair Created Equal? My Skeptical Self Thought So

My initial assumption was that any repair would do, but I quickly discovered that not all methods are created equal. A careless repair can diminish a piece’s value or compromise its integrity. Early on, I once naively trusted a local shop solely based on price, only to see my grandmother’s necklace come back with broken strands and loose clasps. That experience taught me the importance of choosing skilled professionals who use proven techniques, like those outlined in expert appraisal and engraving tips. It’s a mistake I won’t repeat, and I want to help you avoid it.

So, if you’ve ever hesitated to trust a repair shop or felt unsure about the quality of services, you’re not alone. This article will walk you through what makes expert techniques so essential and how they foster lasting trust—so you can cherish your jewelry confidently, knowing it’s in good hands. Ready to discover the secrets behind reliable jewelry restoration? Let’s dive into the key strategies that build trust and preserve beauty.

Prepare Like a Pro Before Repair

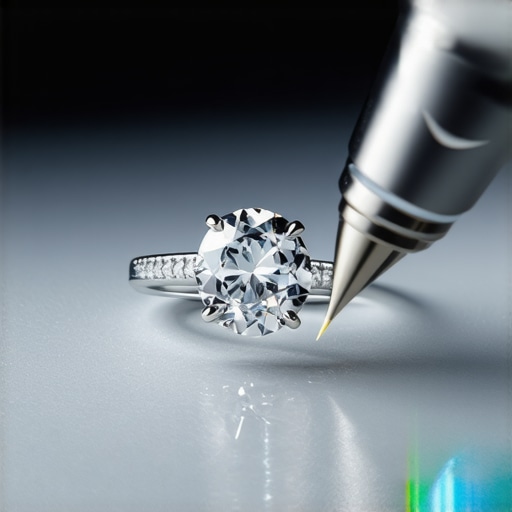

Start by thoroughly inspecting your jewelry piece under good lighting to identify all damage points, loose settings, or weak links. Use a magnifying glass for detailed assessment. For example, I once examined a vintage ring and noticed tiny solder joints that looked dull—signs of weakness. Knowing exactly what needs fixing prevents surprises later and saves time.

Choose the Right Techniques forEach Repair

Properly matching materials and methods is crucial. For stringing, opt for silk or nylon threads that mimic the original, and ensure knots are tight and secure. When engraving, select the appropriate bur or graver based on the design’s detail. I once attempted a simple design on a silver bracelet with a dull engraver—resulting in uneven lines. Using the correct tool and technique is vital for a clean finish, similar to the precision needed in engraving and restringing to ensure durability.

Implement the Proper Re-stringing Process

Remove the old thread carefully, noting the spacing and tension of each knot. Use a new silk or nylon thread of the same thickness. When threading beads onto the string, keep consistent tension to prevent curling or gaps. In one instance, I used a micro needle to feed the thread through beads—prolonged some effort, but resulted in a tight, evenly spaced strand. This meticulous process builds confidence in the repair’s strength, and you can also rely on re-stringing services for expert handling.

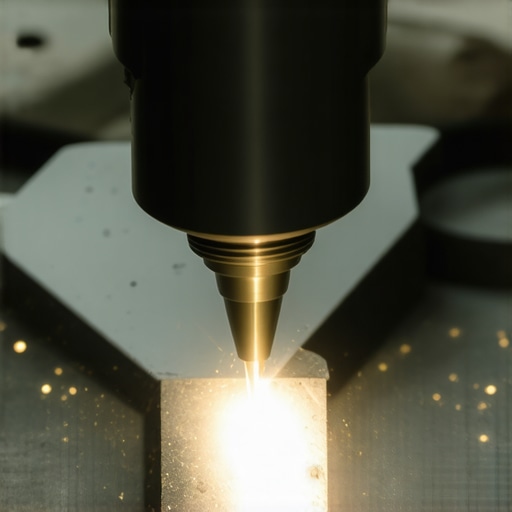

Employ Accurate Engraving Techniques

Secure the jewelry piece in a stable clamp to prevent movement. Use a steady hand and consistent pressure when engraving. For personalized touches, practice on scrap metal to develop control. I once engraved initials on a locket, initially crooked—work that took patience and proper technique. Precision tools like rotary engravers or gravers can dramatically improve outcomes and foster trust, as detailed in expert engraving techniques.

Assess and Certify the Result

After completing repair or engraving, double-check stability, alignment, and finish quality. Clean the jewelry thoroughly—removing fingerprints or residue that can obscure flaws. Take clear photos to document your work, which supports transparency and trust. I learned that sharing authentic before-and-after photos during inspection greatly reassures clients, especially when they see meticulous attention to detail, aligning with appraisal and trust-building strategies.

Many believe that all jewelry repairs are simple fixes, but in my experience, this can lead to costly mistakes. One widespread myth is that DIY repairs are just as reliable as professional servicing, yet advanced techniques like precise re-stringing and engraving require specialized skills and tools. Attempting to do it yourself often results in damage or compromised integrity, undermining the very sentimental or monetary value you wish to preserve. Recognizing these nuances is vital for safeguarding your jewelry.

A frequent trap is underestimating the importance of material compatibility. For example, using the wrong type of thread or adhesive can cause deterioration over time, something even seasoned hobbyists might overlook. Proper knowledge about the *nuances of materials* — such as silk versus nylon, or different metal alloys — ensures longevity and trustworthiness. In my professional journey, I’ve seen cases where improper choices led to irreversible damage, a reminder to always consult expert guidelines or professionals.

What advanced mistakes do amateurs commonly make that compromise the piece’s value?

One critical mistake involves neglecting the precise aesthetic and structural aspects during engraving or setting work. For instance, rushing engravings without proper stabilization can lead to uneven lines or surface damage, which screams amateurism to seasoned eyes. Techniques like securing the piece firmly and practicing with the right tools—such as rotary engravers—are essential for flawless results. As highlighted in expert advice, mastering these advanced techniques not only enhances the quality but also builds trust with clients and keeps your jewelry’s value intact.

It’s also important to avoid misconceptions about certification and appraisal. Many believe that the mere presence of a certificate guarantees quality; however, the *nuance* lies in the evaluator’s expertise and the methodologies used. According to a study by the Gemological Institute, regular updates and certifications by trusted professionals significantly increase confidence and actual value. Misjudging this can lead to undervaluation or disputes, highlighting the importance of working with certified appraisers.

Have you ever fallen into this trap? Let me know in the comments. Proper understanding of these subtle yet impactful aspects can make the difference between a successful repair or an irreversible mistake. Always strive to approach jewelry repair with an eye for detail, professionalism, and respect for the craft.

Keeping It Working: My Favorite Equipment for Jewelry Repair

Maintaining and restoring jewelry demands precision tools that deliver consistent results. One of my top choices is the Swiss-made rotary engraving machine. I prefer it because its durability and smooth control enable me to execute intricate designs without risking surface damage. Its variable speed settings give me the flexibility to work on delicate areas or add detailed engravings, boosting both confidence and trust in my craftsmanship. For precise tension control during re-stringing, I rely on a quality micro-torque knotter, which ensures uniform tension across beads, preventing gaps or curling. These tools are invaluable, especially when dealing with vintage or high-value pieces where perfection matters.

Another device I recommend is the ultrasound cleaning system. Regular cleaning prevents buildup of dirt or residues that can weaken settings or obscure flaws, prolonging the lifespan of jewelry. These systems use high-frequency vibrations to dislodge debris from hard-to-reach areas, ensuring your pieces stay pristine over time. Pairing this with a polarized magnifying microscope allows me to examine detailed work thoroughly, identify potential issues early, and verify the quality of each repair or engraving—building trust through transparency.

The Role of Software in Modern Jewelry Maintenance

In recent years, software solutions like CAD (Computer-Aided Design) programs have revolutionized jewelry design and restoration. Using CAD software, I can create precise digital models of jewelry pieces, plan engravings, and simulate repairs before physical work begins. This minimizes errors and enhances client confidence, knowing that the design is carefully vetted beforehand. Advanced CAD tools also facilitate custom engraving designs, making personalized touches more accessible and accurate. As technology advances, I foresee an increased integration of AI-driven analysis to predict wear points and suggest preventive maintenance steps—ensuring jewelry remains in top condition for years to come.

How do I maintain my tools over time?

Regular calibration and cleaning are essential for maintaining high precision. I schedule monthly inspections of my rotary engraver and ultrasound cleaner, replacing worn parts proactively. Using manufacturer-specific lubricants ensures that mechanical components operate smoothly, preventing unexpected breakdowns. Keeping software updated guarantees compatibility with new design features and security patches. Investing in quality storage solutions, such as padded cases and silica gel packs, keeps my tools free from dust and moisture. These practices extend their lifespan and ensure your tools perform reliably when every detail counts.

In future, I believe the trend toward multifunctional, compact tools combined with intelligent diagnostics will make jewelry maintenance more efficient and accessible. Trying out these advanced tools and maintenance routines now can elevate your craft, build trust with clients, and ensure lasting beauty and integrity of your jewelry pieces. For instance, integrating CAD workflows with expert engraving techniques can significantly boost your confidence and the trust clients place in your work—check out this guide for more on combining design precision and craftsmanship.

What I Wish I Knew About Trusting Artisans Early On

Spotting a skilled jeweler isn’t just about seeing their tools—it’s about feeling confident in their craftsmanship. My biggest lightbulb moment was realizing that building trust requires transparency and consistency, not just fancy equipment. Once I started asking detailed questions about their techniques and materials, I saw real differences in results and confidence. Don’t settle for surface impressions; look for professionals who openly share their repair processes and have a history of satisfied clients.

My Recipe for Elevating Jewelry Repair Confidence

Over time, I’ve curated a toolkit and set of methods that ensure dependable results. My top recommendations include the expert appraisal and engraving tips that reinforce trust through quality, and the professional re-stringing services that safeguard delicate pieces. These resources have helped me deliver lasting value, proving that trust is built through consistent, high-quality craftsmanship.

Trust Is a Journey—Not a One-Time Deal

My most valuable insight is that trust in jewelry repair is cumulative. Each successful adjustment, each transparent communication, adds to a growing foundation of confidence. When I focus on meticulous work and honest dialogue, clients (including myself) feel more secure. Remember, the future of jewelry maintenance hinges on authenticity and a willingness to invest time in perfecting every detail. Trust me—your jewelry’s story is worth it. What steps have you taken to ensure your jewelry gets reputable care? Share your experience below.

![5 Hidden Signs Your Ring Prongs Are Failing [2026 Checklist]](https://jewelryfixpro.com/wp-content/uploads/2026/02/5-Hidden-Signs-Your-Ring-Prongs-Are-Failing-2026-Checklist.jpeg)

![3 Subtle Signs Your Diamond Is About to Fall Out [2026]](https://jewelryfixpro.com/wp-content/uploads/2026/02/3-Subtle-Signs-Your-Diamond-Is-About-to-Fall-Out-2026.jpeg)